- Joined

- Feb 1, 2015

- Messages

- 9,602

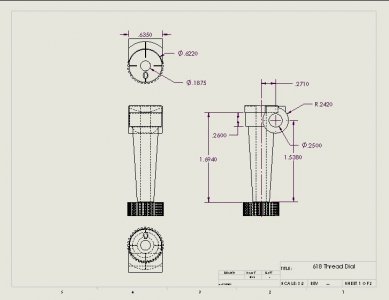

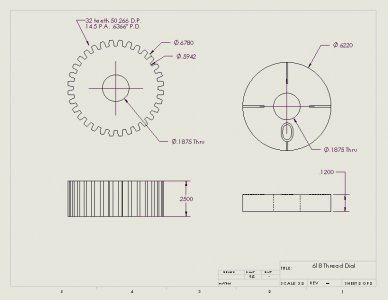

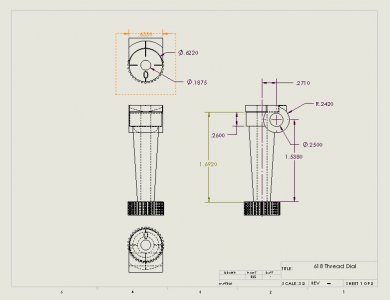

The critical dimensions are the bore for the shaft, the perpendicular mounting hole, and the relationship between the two is the distance from the mounting hole to the lower end of the shaft bore. I can pull mine off my Atlas/Craftsman 6x18 and make some measurements. The tough one will be the gear. It is a 32 tooth gear with a profile to fit the Acme thread of the lead screw. Roughly measuring the diameter pitch, the o.d. measured .675" and the d.p. calculated to 50.37 which is not a standard pitch so a custom cutting tool would need to be made to cut the teeth. There was a method for cutting gear teeth using a slitting saw floating around recently. The width of the blade would need to be .027" o thinner to cut the root of a properly profiled tooth but since there is essentially no load on the gear, you could get away with a simple straight cut on the diameter with a .032" width blade.

Let me know if you want to proceed and I will disassemble mine and blueprint it.

The Clausing parts numbers for my lathe are:

threading dial assembly, 3950-18

dial, M6-62

body, threading dial, M6-63

gear, M6-64A

shaft, M6-65

Let me know if you want to proceed and I will disassemble mine and blueprint it.

The Clausing parts numbers for my lathe are:

threading dial assembly, 3950-18

dial, M6-62

body, threading dial, M6-63

gear, M6-64A

shaft, M6-65