- Joined

- Apr 18, 2016

- Messages

- 50

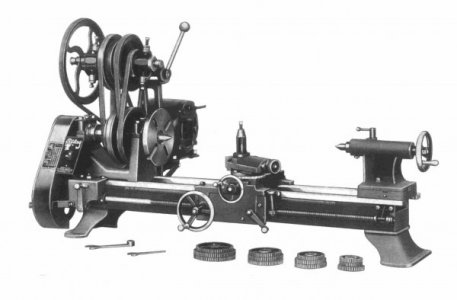

This lathe was given to me by some friends whose neighbor gave it to them many moons ago. It has sat in a barn since then.

All the shafts turned freely from the start. The motor runs (I rewired it before I even tried it). The saddle was clamped in place and slightly stuck, but freed up pretty easily.

Along with what is pictured here ( http://fairwindsfarm.org/Pictures/ ) came the lantern style tool post, a 4 jaw independent chuck, many tool bits, a few wrenches, a steady rest, and a full set of change gears.

The jaws of the 3 jaw have freed up pretty well. I have yet to tackle the four jaw.

Any thoughts on how to hold the spindle still as I take the chuck off? I don't see any obvious "locking" mechanism...

More posts and pictures to come as I poke and prod and see how things shape up.

All the shafts turned freely from the start. The motor runs (I rewired it before I even tried it). The saddle was clamped in place and slightly stuck, but freed up pretty easily.

Along with what is pictured here ( http://fairwindsfarm.org/Pictures/ ) came the lantern style tool post, a 4 jaw independent chuck, many tool bits, a few wrenches, a steady rest, and a full set of change gears.

The jaws of the 3 jaw have freed up pretty well. I have yet to tackle the four jaw.

Any thoughts on how to hold the spindle still as I take the chuck off? I don't see any obvious "locking" mechanism...

More posts and pictures to come as I poke and prod and see how things shape up.