-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Atlas 954 Lathe

- Thread starter Reuben Bailey

- Start date

- Joined

- Apr 18, 2016

- Messages

- 50

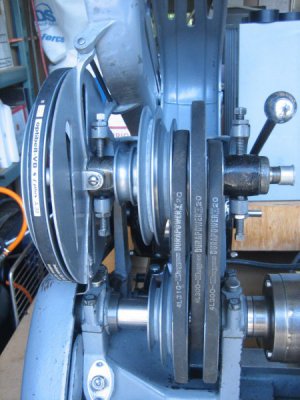

Those look like they will be what I use for the direct and compound belts. I'll start there for the motor to countershaft as well. The one that came on it is a 490 or so and ridiculously oversized. Not sure what the story is with it.

Sent from my iPhone using Tapatalk

Sent from my iPhone using Tapatalk

- Joined

- Nov 27, 2015

- Messages

- 603

I see your pictures, using Tapatalk. I would suggest that when you post them you use the medium resolution. It looks like you used small.

Steve Shannon

Steve Shannon

- Joined

- Apr 18, 2016

- Messages

- 50

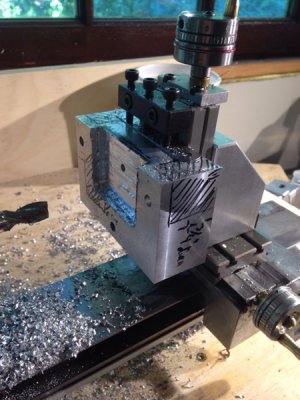

The "transmission casting" replacement in the making - working the Taig to it's physical limits in terms of size and clamping ability. The original block of aluminum was 1 1/2 X 2 1/2 X 3 3/4 inches. Fly cutting the big faces was just barely possible with the cutter set at about 3" or just over. setting up to bore the shaft hole will be interesting - thinking I will be making a custom t-nut to mount the tool post from this on the Atlas for the boring so I can use the larger faceplate - the one I have for this is not big enough, and I don't have the right tool holder at the moment for the Atlas. A spindle adapter is also in the works for mounting the Taig chucks and milling tools on the Atlas until I can get more appropriately sized tooling for the Atlas.

Sent from my iPhone using Tapatalk

- Joined

- Apr 18, 2016

- Messages

- 50

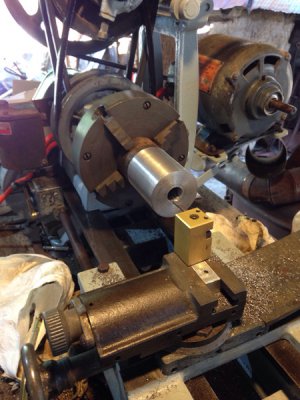

The Atlas is pretty much back together - I have the carriage off for checking clearances on the transmission fitting. The piece in the chuck is turned to within .001" after a light finishing cut.

I have yet to bolt and level it. Lead screw works nicely. Having the hand wheel for rapid traverse will be good.

Sent from my iPhone using Tapatalk

- Joined

- Apr 18, 2016

- Messages

- 50

The beginnings of the spindle adapter - I have made a tee nut tapped to accept either the Taig tool post or the Taig milling slide, so tooling choices are increased nicely.

The shop space that this is in is being expanded - that is the reason for the open wall behind both the Atlas and it's little brother, which has now joined it here. They will both be moving to Alberta with me at the end of next month.

Sent from my iPhone using Tapatalk