- Joined

- May 17, 2012

- Messages

- 104

My Craftsman version is in pieces in the basement. I got out my magnet, and found that the Driver Gear MF-33A, the gear on the spindle , the tumbler gears MF-101-24A and MF-101-20A, the dual gear MF101-16L and MF-101-16, were magnetic. All the rest were non-magnetic (not including the gears on the table, I don't have that open). It seems that all the magnetic gears have bronze bushings, while the Zamak ones do not.

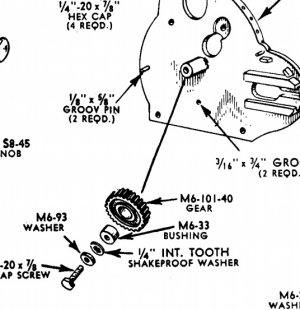

On a related tangent, my parts list shows that there is an internal toothed "shakeproof" washer between the M6-93 washer and the gear and bushing on gear M6-101-40, which is the gear after the stacked gears after the tumbler

. My mill came with a hardware store washer in the place of the M6-93 washer. I made a new M6-93, and when I torqued the screw down, the gear had enough (perhaps excess) clearance that it ran freely. Does anyone know why only this gear would be specified with a toothed washer for which I see no purpose?

On a related tangent, my parts list shows that there is an internal toothed "shakeproof" washer between the M6-93 washer and the gear and bushing on gear M6-101-40, which is the gear after the stacked gears after the tumbler

. My mill came with a hardware store washer in the place of the M6-93 washer. I made a new M6-93, and when I torqued the screw down, the gear had enough (perhaps excess) clearance that it ran freely. Does anyone know why only this gear would be specified with a toothed washer for which I see no purpose?