New Parts:

Thought I'd post some of the newly manufactured parts that are available online if someone is new like me and working on a atlas lathe.

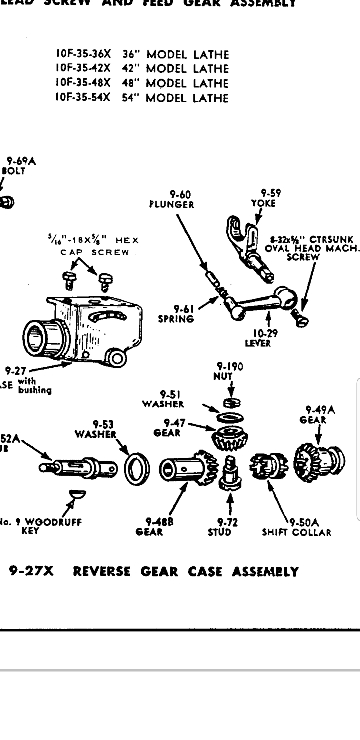

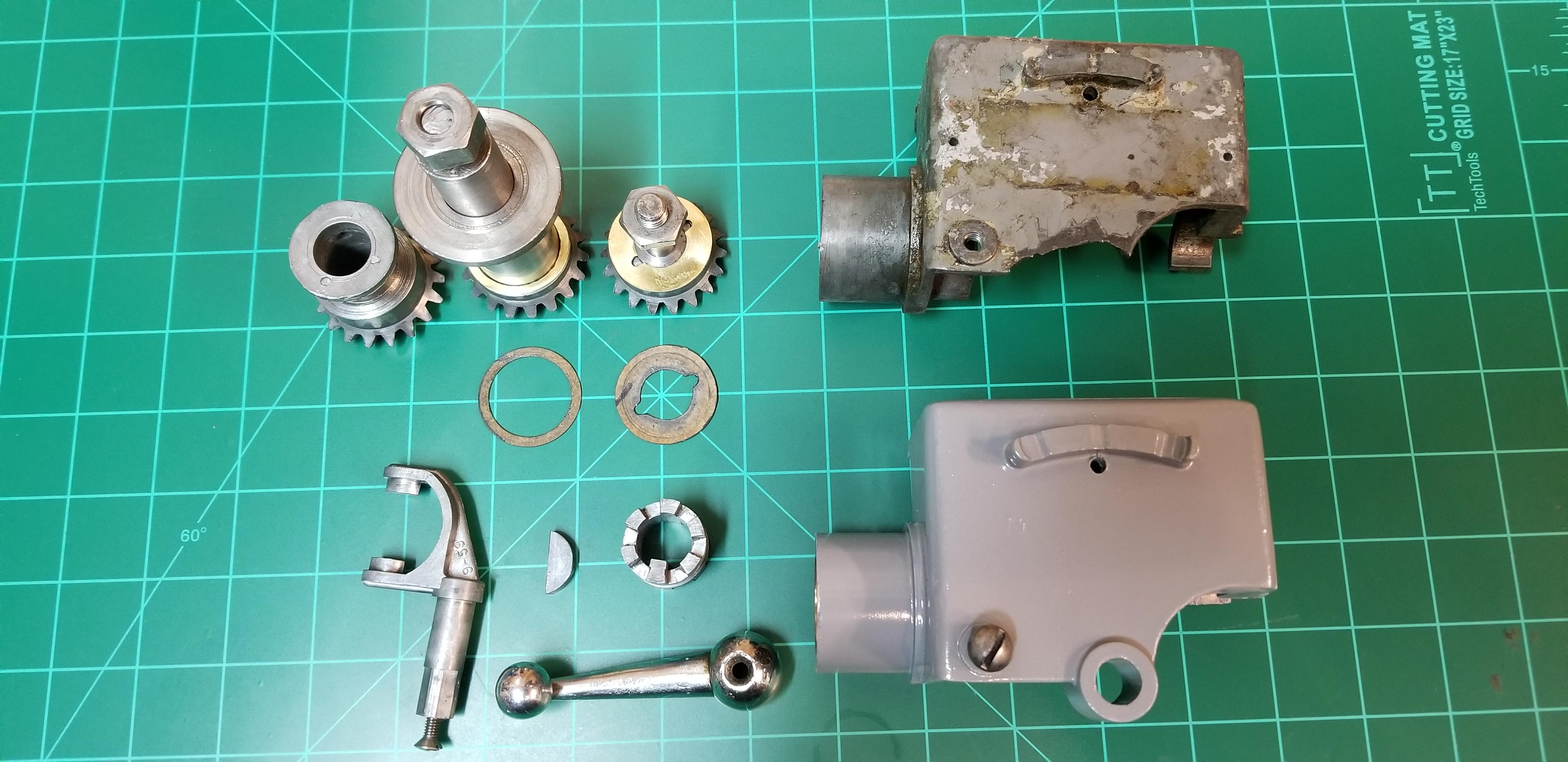

My lathe had a crash that appears to have originated from the change gears or threading use. My lathe broke everything that is commonly breakable in the atlas lathe series when a crash occurs and then some. Probably why it was taken out of service back in day.

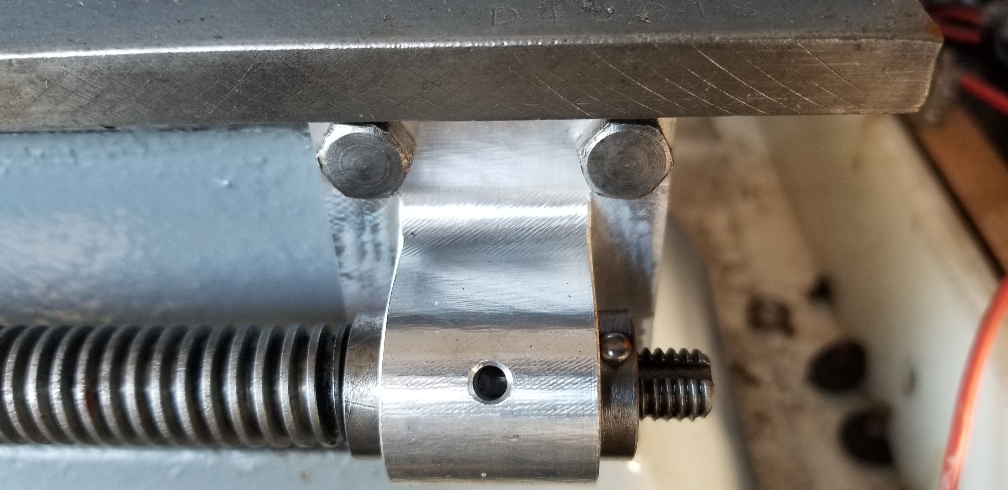

One thought (just a thought lol) looking at the photo below I purchased two sleeves. They are I think steel sleeves with brown plastic bushing instead of the original metal bushings. If one is not using the aftermarket plastic change gears this might help save the lathe during a crash were hopefully the plastic will give way before other major damage occurs.

The traverse gear box is aluminum with steel gears and should never break again. Wait to you see the photos of the original one when I post the saddle/apron work.

KNOW YOUR LATHE:

Just a word of caution... not all the atlas lathes share the same parts even though they look similar!! If your working on a atlas 10D they have the older 5/8 lead screw. I believe all the other 10" and 12" models have the 3/4 screw. This means all the parts shown in the below photos will not fit the lathes with the 3/4 screw. However if you are working on the newer 3/4 leads screw 10" lathes they are available at this time. The 9" and 10D however shares the same 3/4 screw and alot of parts ar interchangeable between them. Another note I believe all the 9" 10" and 12" lathes share the same change gears with the exception of the newer version have more gear options. Also I believe all the 9,10 and 12" lathes share the same forward/reverse gearbox for the 3/4 lead screw is tapered down on the ends to 5/8. The 10D box had the original atlas name plate on the casting however I don't think the other 10 and 12" lathes had it. None the less with or without the name plate I believe they are the same. My box was off a atlas THF and fits nicely on the 10D. Yeah I know confusing so do your homework before purchasing!!

Things are a bit slow because of the heat in Florida however I will be updating the completed headstock shortly as I'm just doing some final work on the gears.

Dave

Sent from my SM-N950U1 using Tapatalk