For all of you watching and supporting me in this thread thank you!! And sorry I been busy with work and other projects in the garage however I have made some progress....

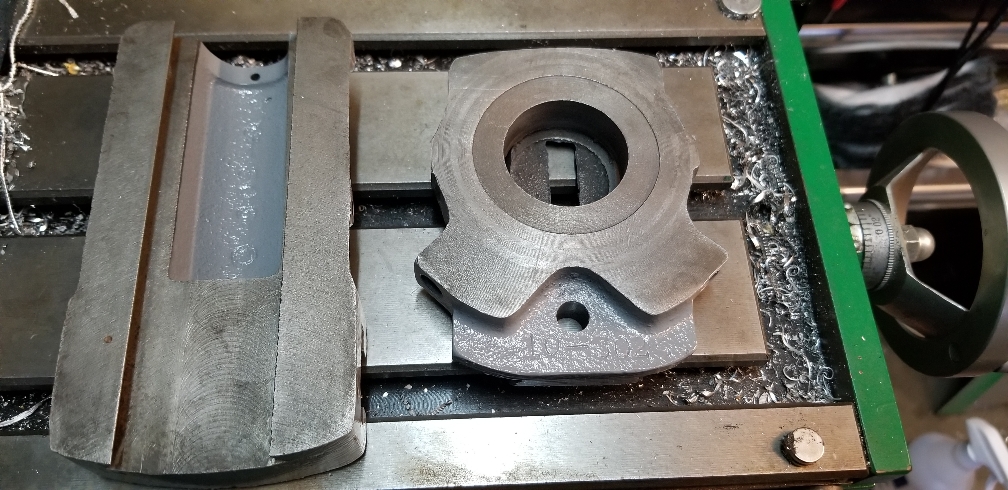

Apron / carriage assembly: all I can say is wow alot of work on this section.

1) All new screws and newer style gib screws with locking nuts.

Normally I like to use the original screws when possible however changing the slotted screws that hold the bearing plates makes it easier to work with.

Locking nuts for the new gib screws to hold them in place were the originals didn't have them.

I changed all the square bolts out in the lathe for they had all stripped. They were replaced with grade 8 bolts and the one on the apron I have placed a rubber washer underneath it's normal washer.

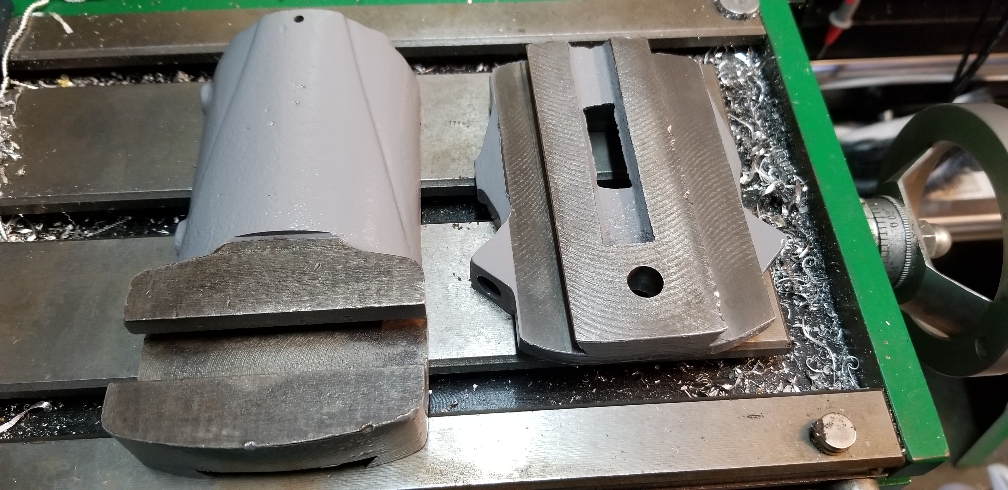

2) Bearing plats were flipped around for they had some ware on one side of them. One plate I had to open the holes to allow the screws to fit.

3) Bearing plates shims. The original shims according to the manual should be .002 to .003 inches. My shims were. 0025 to .003 however I had to add .002 shims to the original shims for without them the carriage was to stiff sliding across the ways. I'd imagine I will have to tweak this section more during final alignment.

If your working on a 10-D lathe the above values my be different for you.

4) New parts!! Expensive however I'm very grateful that folks are still making stuff for the old lathes!!!!

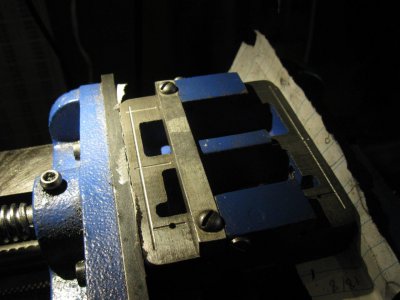

5) New half nuts. I had to file down the edges until they worked smoothly.

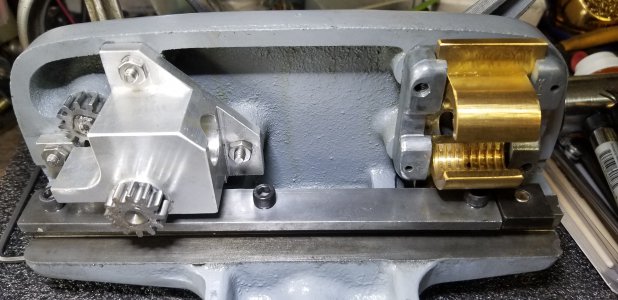

6) New travers assembly. The case is aluminum and the gears are steel. The original screws I believe were 1/4 - 20 however using that size didn't allow any movement for adjustment when bolting it to the apron and meshing properly was a problem. The original case appears to have slotted screw holes for adjustment were the new case didn't.

The fix: simply went with 10-32 stainless screws and bolts. The smaller size now allows for adjustment.

Look up in the posts you will find the photo of the orginal assembly with a totally useless travers assembly.

7) know your lathe!! I have mentioned this before for new people like myself working on the atlas lathe line. The model 10-D isn't the same as a model 10. When ordering new parts for the 10-D make sure it's for a 5/8 lead screw. The 10-D I find is the hardest lathe to find NEW parts for were the 6, 10, and 12 inch lathes are more readily available. The 9 inch lathe falls into the same hard to find new parts as the 10-D.

8) Handles are still a problem for I'm missing some and others are broken.

9) Working on the threading indicator and will post that shortly.

Thanks

Dave