Hello all,

My first time posting here, so I hope I’m in the correct spot.

My neighbour has acquired a new to him lathe, and really doesn’t know much bout it. He’s a retired machinist, and not adept at the internet, so I offered to help him. My research has led me to this site. Lots of info here. I’ve been working in the aircraft maintenance industry, dabbling in machining work. Mostly making a few simple parts here and there, bushings etc. So I’m happy to have come across this site and look forward to learning more.

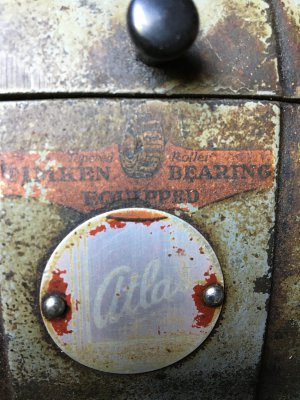

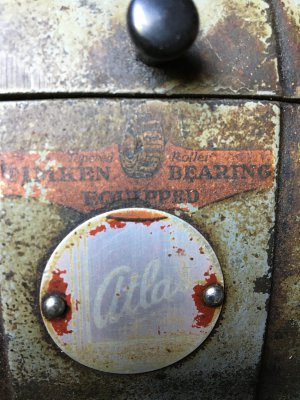

The lathe in question is an Atlas, that much I know, but that’s about all we know. From my research I think it is a 618? I am assuming that means it is a 6” x 18”. It seems to be in working order, but needs new belts. Any other into would be appreciated. I did find this site:

Thanks for the help, look forward to reading more threads.

My first time posting here, so I hope I’m in the correct spot.

My neighbour has acquired a new to him lathe, and really doesn’t know much bout it. He’s a retired machinist, and not adept at the internet, so I offered to help him. My research has led me to this site. Lots of info here. I’ve been working in the aircraft maintenance industry, dabbling in machining work. Mostly making a few simple parts here and there, bushings etc. So I’m happy to have come across this site and look forward to learning more.

The lathe in question is an Atlas, that much I know, but that’s about all we know. From my research I think it is a 618? I am assuming that means it is a 6” x 18”. It seems to be in working order, but needs new belts. Any other into would be appreciated. I did find this site:

Thanks for the help, look forward to reading more threads.