- Joined

- Aug 6, 2015

- Messages

- 3,885

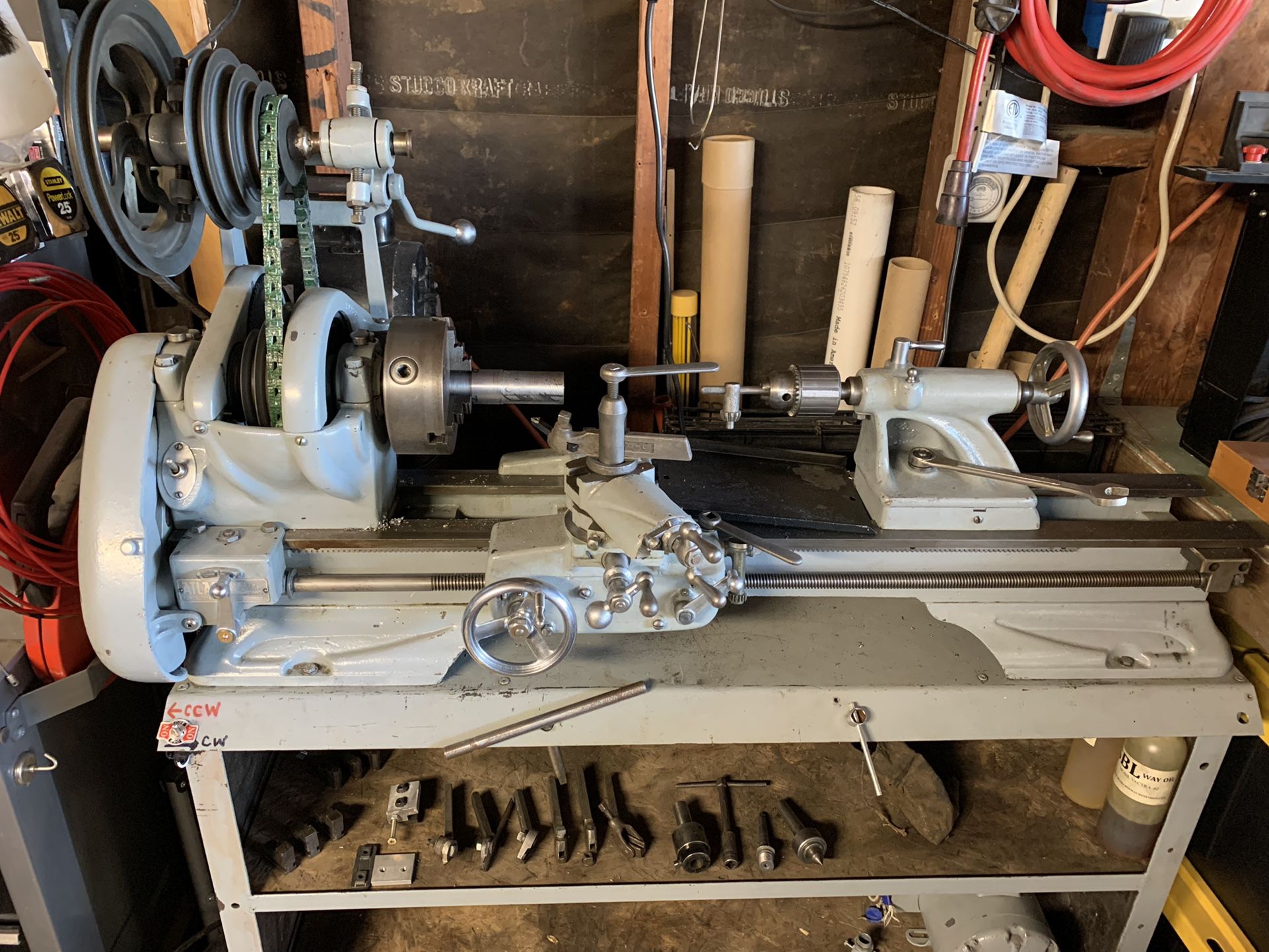

If what you really want is a project lathe, have a look at the South Bend: you'll have a much better

machine in the end though you might not want to sell it when your done.

That one is a good 4-hour drive away... Have not bother to call the seller... And they are asking 1200.00 for it. So even if I negotiate down, it will be closer to 1K. Too much hassle trying to pass that with the Finance department at home

Here is one for comparison in my neighborhood to maybe help with bargaining

10 inch Atlas Craftsman lathe 42 inch bed in working condition. for Sale in San Diego, CA - OfferUp

Used (normal wear), Come check it out. . Make an offer!;offerup.com

Thanks. If the seller is not willing to accept 500.00 I will just walk away with no regrets... If he does accept, oh boy... I am going to have to drive straight to Ocala and hide it there somewhere... If I get home (Orlando) with it, there is going to be a lot of explaining to do, lol...

And who am I kidding... if I get the Atlas, there is no selling anything... I will end up with three lathes...