Glad to hear you find it so useful, shapers are dismissed by many as obsolete, and little shapers in particular get tagged as cute but pointless. I have no experience with them, but they are neat little machines and the price was right. I really don't know what I'll do with mine, but they seem to have a few niches to fill. I like machinery, and learning how to use it. Finding the jobs that they can do, even if another machine can do it, or potentially even do it better. I have a small horizontal mill as well which can do many but not all the jobs of a shaper. Where a real machinist often looks at efficiency for me it is mostly about the process of making something. A slower way that uses more of the toys is a plus for me, because I'm not trying to feed myself with my shop, just feeding my brain by trying different things.

Unfortunately mine didn't come with the correct vise, it came with a 3" screwless vise which seems like it will work for now, and should also be a useful addition to use with my mills. My horizontal mill came with a 4" low profile Palmgren vise which looks very similar to the Atlas shaper vise, so it may get shared. It is also missing all the loose bits, no tool holders, wrenches, crank handle etc. My guess is this came out of an estate and as so often happens these were probably in a box that went somewhere else.

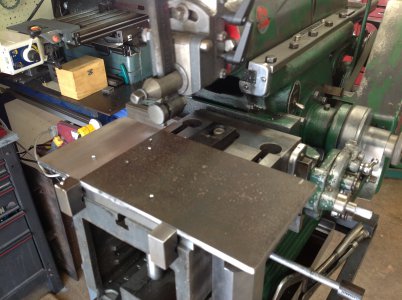

It needs some cleaning up, and a few small repairs but it runs with no scary noises. I could probably turn out some parts as it is. Serial number is in the mid 13,000 range so I'm guessing it was near the end of production, late 50s / early 60s as I've not seen any listed with a serial of 14,000 or higher and from what I've read Atlas ended shaper production in 1961.

I didn't even think about jigs and such for work holding but that certainly makes sense. There is a post here on the site with plans for a shaper vise, so another project.

I know I could easily find an existing commercial stand that works, but I've got a welder and currently have access to sheet metal tools, so I thought something styled after the Atlas stand would look good, but having a small shop I need to be efficient with space and the factory cabinet did not seem to give much thought to storage.

The drain line from the drip pan makes sense. My horizontal mill has one, although that is for coolant used rather than the machine dripping with oil.

I have small horizontal and vertical mills so I do have a lot of tooling that cross pollinates, like rotary tables, a dividing head etc but they already have homes so I don't need to find a spot on the stand for them.