Nothing against them but Jere is making stuff that looks just as good for a fraction of the cost. Makes me wonder if those sheetmetal guys have a full on machine shop or shop out their designs.

I also have tons of respect for all other fabricators you mentioned but when it comes to follow a design, I know Jere's is the easiest to understand and that alone gives me the confidence to try his ideas first., the bottom line is functionality isn't it.

So are you doing your washers exactly like Jere did with the welded on tab/key? That seems harder than just broaching the washer and using a key. But I might be missing something. Jere almost always has a reason for what he does. Did you do that whole crazy set of spacers too?

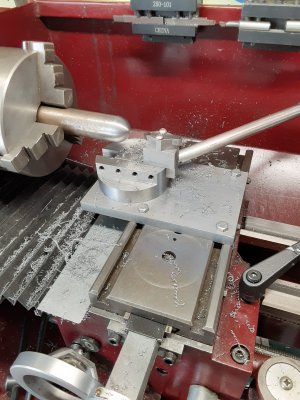

Yes I did them almost exactly like Jere did except I cut a small 1/8"X 1/4" notch where the tab/key goes and then put a tack weld with my Mig, the completed the weld outside on the table, then grinding them flat on the belt sander, the tabs were cut from a flat bar(cold rolled) to size 3/8" long 1/4" wide. the dies came out great if I may say so myself, beveled the edges on my mini lathe using a flat file.

I'm now planning on making full size dies (same size as the ones that came with the bead roller) but out of 2" aluminum rod . I don't need to use steel since I mostly use thin copper( or brass/aluminum) for my projects. I'm thinking, If Jere recommends skateboard wheels for dies, then Aluminum can't be too far behind.

And as far as spacers go, I bought a piece of steel tubing from HD (1"OD X.056" X36"long) which is a perfect size for spacers, you don't need to bore it to size, just grind the flashing ,that's all, the hard part was the width of these spacers, it may take a few proper measurements to get the exact length(or width?). the .065" wall thickness is a perfect fit for HF/Princess Auto bead roller shafts.