To keep the arm from moving to freely just adjust the bearing preload to be stiff. Or make some holes with a corresponding pin on the hub so when stowed one can pin it to lock in position so it can’t spin.

I used a electric winch on mine saves from all the cranking. Hardest part on a vehicle would be finding a solid place to mount the apparatus. Which I would think a 12” square plate 1/4to1/2 thick as the base with large U bolts strattling the frame would work.

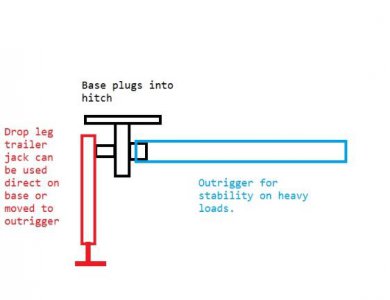

Looking at your post mounting it to the receiver is good but then you will be swinging the load over the bed rails. Which your load will have to be high. Mounting on the side will allow the load to swing center in the bed. Just a thought.

I used a electric winch on mine saves from all the cranking. Hardest part on a vehicle would be finding a solid place to mount the apparatus. Which I would think a 12” square plate 1/4to1/2 thick as the base with large U bolts strattling the frame would work.

Looking at your post mounting it to the receiver is good but then you will be swinging the load over the bed rails. Which your load will have to be high. Mounting on the side will allow the load to swing center in the bed. Just a thought.