Ok - there was a hidden zip type pulled tight by King Kong at the front - I had clipped the one at the back.

Picture below.

Ext - ran through the process.

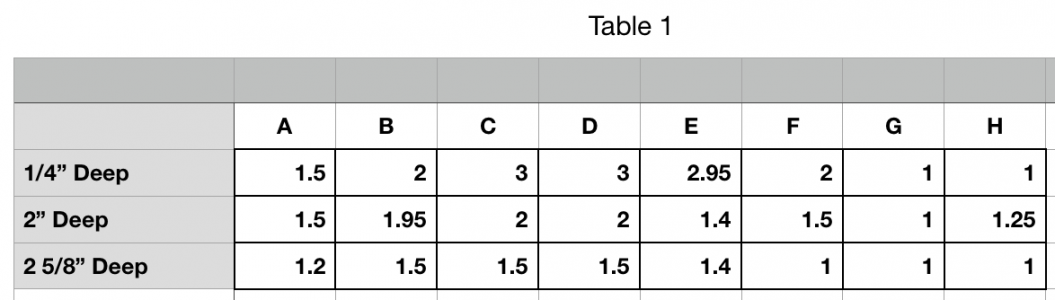

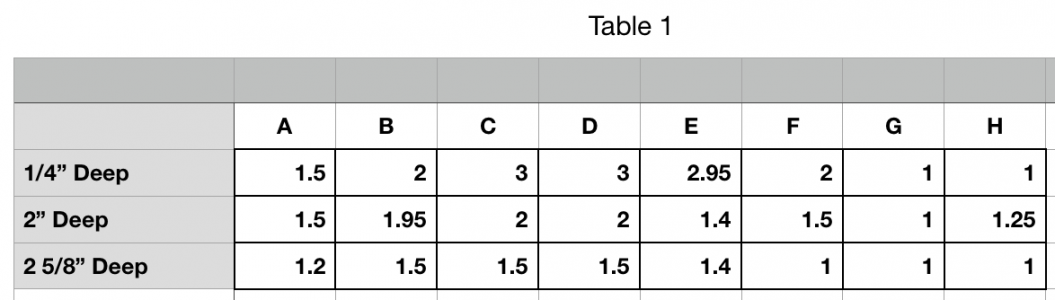

Marked where the front dog was as A - rear dog as B - and there were three increments between B,C,D and F,G,H

This represented a mark every 45 degrees around the spindle.

I watched for lumps. There are not giant ones - but perhaps a few areas where there was a small tic.

I went ahead and zeroed out putting A at 1.5 and then taking relative measures from that point

However - you can see a pretty consistent read from top to bottom.

All measures are in ten thousandths ("tenths").

Interesting process.

One thing that the old German spindle grinder told me was - you can tell when the bearings are bad because the readings wont be consistent - keeps moving around. I am not seeing that either in slow or quicker motion. Thoughts on that and chart?