- Joined

- May 2, 2021

- Messages

- 330

Appreciate that.I give you credit for jumping in and tackling several significant projects simultaneously while still trying to keep reasonable goals in sight.

Know it can look like spaghetti at the wall sometimes.

Takes one to know one I suspect.

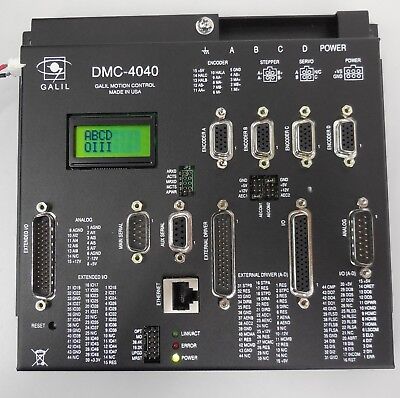

Ok.This whole project is really at a decision point. It is so easy and really less complex to to just add a controller to run the thing, even in manual mode. On my machine when operating manually I use a combination of keyboard jog and hand cranking to accomplish the task. Besides the spindle VFD controls, I only have an E-stop and an Enable button as physical buttons, everything else is done on the computer screen with a mouse click. Eliminates an incredible amount of wiring.

The above lays out the non full CNC play.

My approach on cables (going forward...) will be to disconnect in the big box and feed out and up into the upper box, or out to the component they are controlling.

Suppose I have two questions then

1. How many of each of the links do I need to buy.

2. What is the shopping list if we just go straight to CNC?

Even if imperfect for choice - once I understand the components - I can shop them a bit for size and attachment ease.

Perhaps we should just make the leap now.