- Joined

- Feb 2, 2021

- Messages

- 39

Greetings!

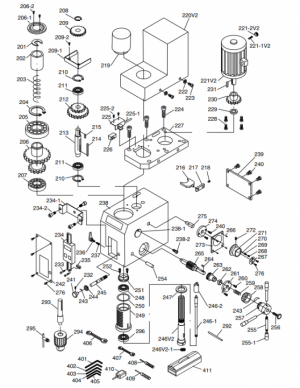

I just installed this belt drive kit and bought new nachi bearings. Has anyone had a significant issues with runnout at the endmill +.01 ? I have a nice vibration with the draw bar setting off center once tightened.

Has anyone installed this kit: https://www.minipro.com/products/g0704

I would love to know what I screwed up on this one.

Best,

Ian

I just installed this belt drive kit and bought new nachi bearings. Has anyone had a significant issues with runnout at the endmill +.01 ? I have a nice vibration with the draw bar setting off center once tightened.

Has anyone installed this kit: https://www.minipro.com/products/g0704

I would love to know what I screwed up on this one.

Best,

Ian