- Joined

- Jun 29, 2014

- Messages

- 4,058

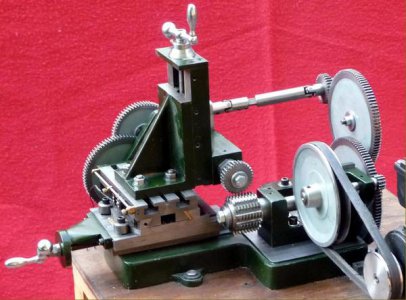

Well, starting the new year off right! I'm now the owner of set of Prestech castings of which when finished, will allow me to hob my own gears. There was an auction on eBay over Christmas and I figured what the heck...

There are 11 iron castings manufactured by Preserved Technology LTD., of Oldham, England along with many prints and articles that the previous owner, Earl H., was very kind to make copies of and pass along.

Pictures of the castings:

The machine base. A little rusty, but easily cleaned up. Not bad for sitting a box for thirty years!

Slide ways and brackets. The gear blank spindle housing block is tucked away on the right side of the photo.

Hob spindle housing casting (top center) and supporting brackets and angle plates.

List of articles at my disposal for the build:

Gear Cutting in the Lathe, by J.A. Radford, Model Engineer, 6 September 1968

Gear Cutting in the Lathe, by J.A. Radford, Model Engineer, 20 September 1968

Hobbing Device, Postbag by Geo. H. Thomas, Model Engineer, 17 December 1971

Hobbing, Postbag by K.P. Wood, Model Engineer, 17 March 1972

Gear hobbing, Postbag by Geo. H. Thomas, Model Engineer, 16 June 1972

A Gear Hobbing Machine, by T.D. Jacobs, Model Engineer, 5 July 1974

Gear Cutting, Postbag by G.H. Thomas, Model Engineer, 6 September 1974

Gear Cutting Machine, Postbag by T.D. Jacobs, Model Engineer, 17 January 1975

Gear Cutting Machine, Postbag by T.D. Jacobs, Model Engineer, 20 June 1975

Gear Machine, Postbag by T.D. Jacobs, Model Engineer, 1 August 1975

Gears and Gear Cutting, by T.D. Jacobs, Model Engineer, 19 September 1975

A Gear-Cutting Machine, by T.D. Jacobs, Model Engineer, 16 January 1976

A Gear-Cutting Machine, part II by T.D. Jacobs, Model Engineer, 6 February 1976

A Gear-Cutting Machine, part III by T.D. Jacobs, Model Engineer, 20 February 1976

A Gear-Cutting Machine, part IV by T.D. Jacobs, Model Engineer, 5 March 1976

A Gear-Cutting Machine, part V by T.D. Jacobs, Model Engineer, 19 March 1976

Gear Cutting, Postbag by C.H. Baker, Model Engineer, 7 May 1976

Gear Hobbing, by T.D. Jacobs, Model Engineer, 16 July 1976

Fluting Taps and Reamers, by T.D. Jacobs, Model Engineer, 6 August 1976

Gear Cutting, Postbag by F. Butler, Model Engineer, 3 September 1976

Gear Cutting, Postbag by I.G.O. Brown, Model Engineer, 3 December 1976

Gear-cutting, Postbag by T.D. Jacobs, Model Engineer, 17 December 1976

An Attachment for backing-off Milling Cutters, by Dr. A.R. Bracey, Model Engineer, 17 December 1976

The 1980 Model Engineer Exhibition Class "N" - Tools and Workshop Appliances, by D.M. Chaddock, Model Engineer, 4 April 1980

Home Made Hobs, by T.D. Jacobs, publisher unknown, drawings contained within dated 1982

The "Helix" Gear Hobbing Machine, by Terry Sexton, publisher and date unknown

There are also a series of articles included from Model Engineer's Workshop by Harold Hall and Chris Robinson. I can't place the dates. These are obviously later articles where the CES kit was either built or modified. There is some sorting out of these articles to do before I add them to this list. I realize my "bibliography" above is not to any academic standard, I'll clean them up as I go.

There is also an E-size drawing of the orthographic views of the assembled machine, gear cutting chart and associated parts list, of which there are 90 unique parts and 128 in total. The drawing is produced by Prestech, or Preserved Technology Limited copyrighted in 1986.

I expect this will take me a better part of 12 months to complete. In the spirit of the namesake of the company, I will first recreate the drawings from the articles in CAD. The current copies will be difficult to work from being small reproductions on letter sized paper.

My understanding is that this can be mostly machined on a 6" lathe, with the exception of the base. I'll bring that into work where I have access to a knee mill. The rest I'll do in the home shop this spring and summer on the 10F.

I'm not anxious about this at all, but very excited and know that I am in for a real challenge. I've made small tools, designed fixtures and machined simple things in the past, but nothing of this nature. Really looking forward to all this has to offer. Any thoughts about this project?

There are 11 iron castings manufactured by Preserved Technology LTD., of Oldham, England along with many prints and articles that the previous owner, Earl H., was very kind to make copies of and pass along.

Pictures of the castings:

The machine base. A little rusty, but easily cleaned up. Not bad for sitting a box for thirty years!

Slide ways and brackets. The gear blank spindle housing block is tucked away on the right side of the photo.

Hob spindle housing casting (top center) and supporting brackets and angle plates.

List of articles at my disposal for the build:

Gear Cutting in the Lathe, by J.A. Radford, Model Engineer, 6 September 1968

Gear Cutting in the Lathe, by J.A. Radford, Model Engineer, 20 September 1968

Hobbing Device, Postbag by Geo. H. Thomas, Model Engineer, 17 December 1971

Hobbing, Postbag by K.P. Wood, Model Engineer, 17 March 1972

Gear hobbing, Postbag by Geo. H. Thomas, Model Engineer, 16 June 1972

A Gear Hobbing Machine, by T.D. Jacobs, Model Engineer, 5 July 1974

Gear Cutting, Postbag by G.H. Thomas, Model Engineer, 6 September 1974

Gear Cutting Machine, Postbag by T.D. Jacobs, Model Engineer, 17 January 1975

Gear Cutting Machine, Postbag by T.D. Jacobs, Model Engineer, 20 June 1975

Gear Machine, Postbag by T.D. Jacobs, Model Engineer, 1 August 1975

Gears and Gear Cutting, by T.D. Jacobs, Model Engineer, 19 September 1975

A Gear-Cutting Machine, by T.D. Jacobs, Model Engineer, 16 January 1976

A Gear-Cutting Machine, part II by T.D. Jacobs, Model Engineer, 6 February 1976

A Gear-Cutting Machine, part III by T.D. Jacobs, Model Engineer, 20 February 1976

A Gear-Cutting Machine, part IV by T.D. Jacobs, Model Engineer, 5 March 1976

A Gear-Cutting Machine, part V by T.D. Jacobs, Model Engineer, 19 March 1976

Gear Cutting, Postbag by C.H. Baker, Model Engineer, 7 May 1976

Gear Hobbing, by T.D. Jacobs, Model Engineer, 16 July 1976

Fluting Taps and Reamers, by T.D. Jacobs, Model Engineer, 6 August 1976

Gear Cutting, Postbag by F. Butler, Model Engineer, 3 September 1976

Gear Cutting, Postbag by I.G.O. Brown, Model Engineer, 3 December 1976

Gear-cutting, Postbag by T.D. Jacobs, Model Engineer, 17 December 1976

An Attachment for backing-off Milling Cutters, by Dr. A.R. Bracey, Model Engineer, 17 December 1976

The 1980 Model Engineer Exhibition Class "N" - Tools and Workshop Appliances, by D.M. Chaddock, Model Engineer, 4 April 1980

Home Made Hobs, by T.D. Jacobs, publisher unknown, drawings contained within dated 1982

The "Helix" Gear Hobbing Machine, by Terry Sexton, publisher and date unknown

There are also a series of articles included from Model Engineer's Workshop by Harold Hall and Chris Robinson. I can't place the dates. These are obviously later articles where the CES kit was either built or modified. There is some sorting out of these articles to do before I add them to this list. I realize my "bibliography" above is not to any academic standard, I'll clean them up as I go.

There is also an E-size drawing of the orthographic views of the assembled machine, gear cutting chart and associated parts list, of which there are 90 unique parts and 128 in total. The drawing is produced by Prestech, or Preserved Technology Limited copyrighted in 1986.

I expect this will take me a better part of 12 months to complete. In the spirit of the namesake of the company, I will first recreate the drawings from the articles in CAD. The current copies will be difficult to work from being small reproductions on letter sized paper.

My understanding is that this can be mostly machined on a 6" lathe, with the exception of the base. I'll bring that into work where I have access to a knee mill. The rest I'll do in the home shop this spring and summer on the 10F.

I'm not anxious about this at all, but very excited and know that I am in for a real challenge. I've made small tools, designed fixtures and machined simple things in the past, but nothing of this nature. Really looking forward to all this has to offer. Any thoughts about this project?