- Joined

- Nov 25, 2015

- Messages

- 335

Hey everyone. As I proceed down the path of life I am generally reminded why my grandfather had so much “junk” when he passed...... because of that age old adage; that as soon as you get rid of it, you’re going to need it! It is with this adage in mind that I pose this to the group.

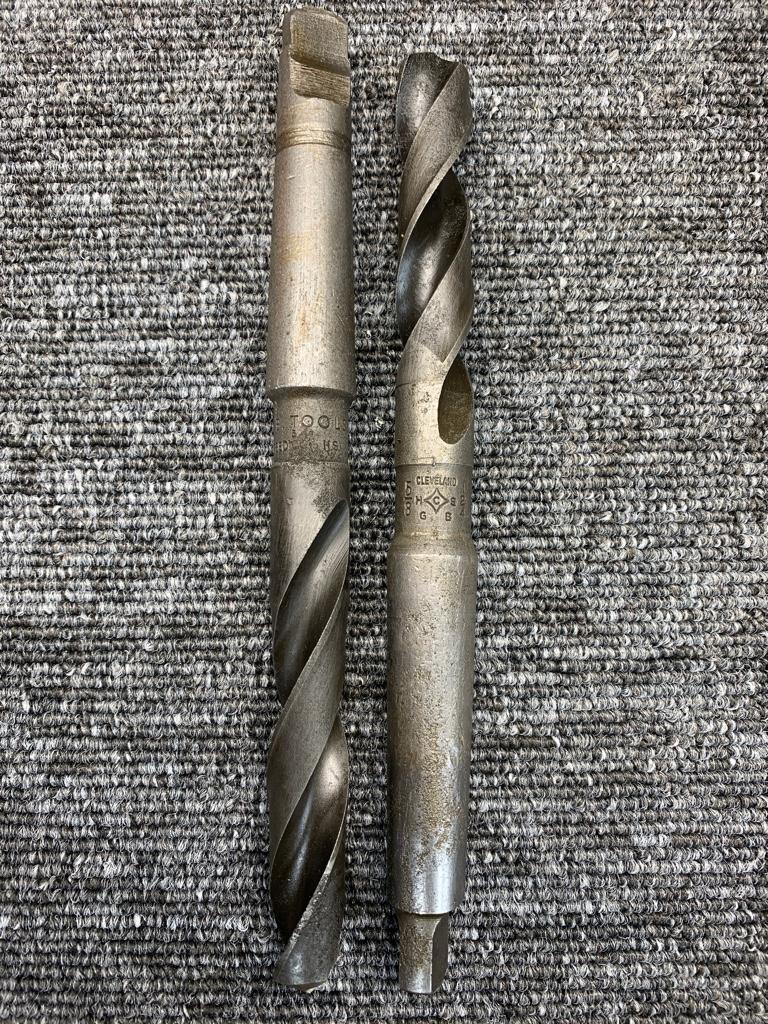

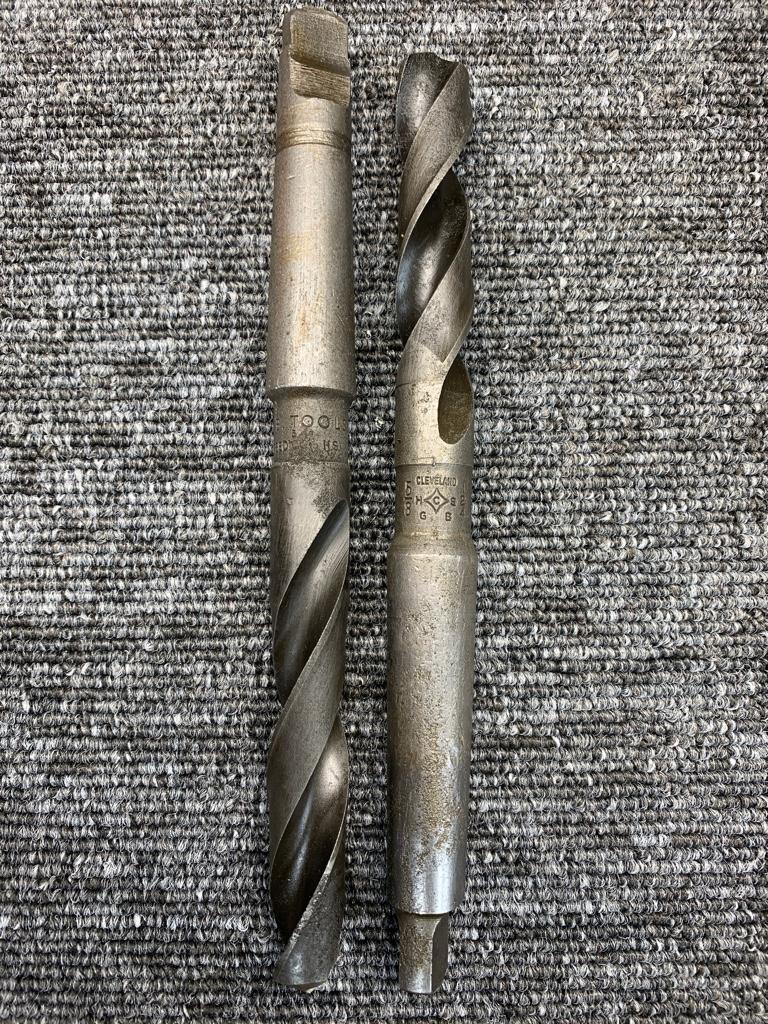

I have drawers of odds and ends. During the Covit “break” I have been organizing and re jigging things in the shop. I came across some tapered shank drill bits that when put into the mill seem to wobble. They are apparently “bent”. Are they garbage or is there a reason to hang onto them?

Regards all.

Derek.

Sent from my iPhone using Tapatalk

I have drawers of odds and ends. During the Covit “break” I have been organizing and re jigging things in the shop. I came across some tapered shank drill bits that when put into the mill seem to wobble. They are apparently “bent”. Are they garbage or is there a reason to hang onto them?

Regards all.

Derek.

Sent from my iPhone using Tapatalk