- Joined

- Oct 28, 2020

- Messages

- 20

I'm a total novice and have been monkeying with my 728 for just under a year. On initial setup I used the tilt adjustment to tram the X axis within a half thou over 6". The Y axis is out by about 2 thou over the same 6", so now I'm trying to figure out what I can do about that. Goal is to adjust the nod forward (top toward the user).

A common approach I observe elsewhere in the forums is to place shims between the column and the base. On other bench mills like the PM-25, the 4 bolts attaching the column to the base are accessible from the top and as a result this seems reasonably straightforward. On the 728VT, these bolts are underneath the base. I think that means I'd have to lift the entire mill off of the base, try and loosen those bolts, insert some shims, and re-tighten the bolts, all while the mill is hanging from my shop crane.

The manual offers this guidance:

Based on this, I'm thinking I should do the following:

1. Loosen the two 19mm bolts for the tilt adjustment

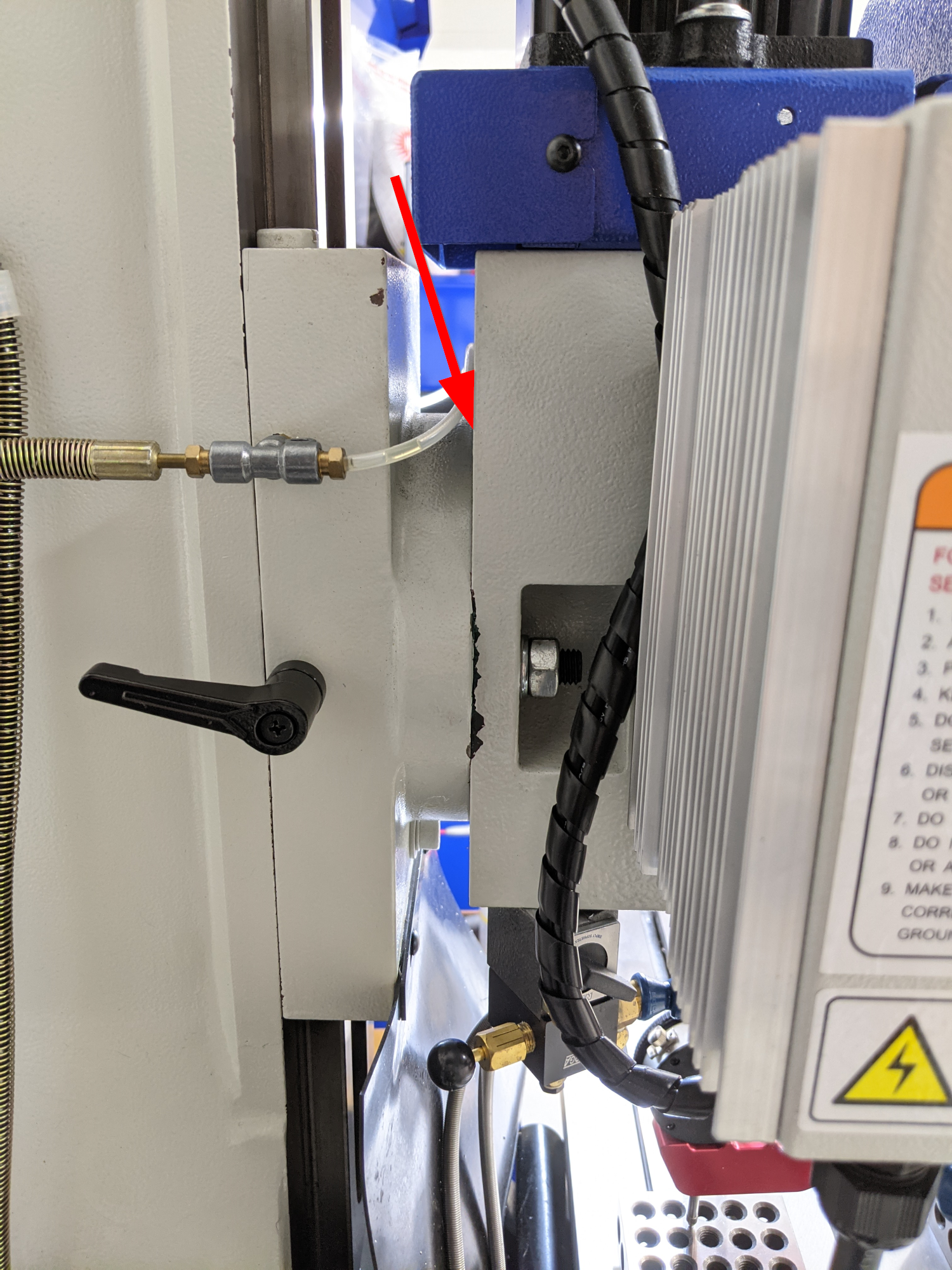

2. Insert shim stock at the top of the interface between the headstock and saddle (red arrow in image below)

3. Tighten tilt bolts

4. Check Y tram and repeat 1-4 as needed

Questions:

1. Does the approach above seem about right? I'm pretty sure this is what the manual is suggesting, but the manual also suggests that this isn't a great idea which doesn't fill me full of confidence. Is there some other approach that might be better?

2. I'm not sure if that surface is precision ground, but it is an adjustment interface for tilt and I feel like I want to avoid scratching it up. Would using aluminium (kitchen foil, soda can, etc) be a reasonable solution here? Thought process is that it's softer than steel and might not scratch that surface. I have access to conventional steel shim stock if that's a better plan.

A common approach I observe elsewhere in the forums is to place shims between the column and the base. On other bench mills like the PM-25, the 4 bolts attaching the column to the base are accessible from the top and as a result this seems reasonably straightforward. On the 728VT, these bolts are underneath the base. I think that means I'd have to lift the entire mill off of the base, try and loosen those bolts, insert some shims, and re-tighten the bolts, all while the mill is hanging from my shop crane.

The manual offers this guidance:

If more precise tram is called for, it can be adjusted by sandwiching a metal shim between the headstock and its sliding base (saddle) on the column. It is more likely that the headstock is nodding forward rather than leaning backward, so start with (say) a 1 mil (0.001") shim in the bottom quadrant of the machined mating surfaces between headstock and saddle. This is a temporary fix that may not be satisfactory if the headstock is subsequently rotated.

Based on this, I'm thinking I should do the following:

1. Loosen the two 19mm bolts for the tilt adjustment

2. Insert shim stock at the top of the interface between the headstock and saddle (red arrow in image below)

3. Tighten tilt bolts

4. Check Y tram and repeat 1-4 as needed

Questions:

1. Does the approach above seem about right? I'm pretty sure this is what the manual is suggesting, but the manual also suggests that this isn't a great idea which doesn't fill me full of confidence. Is there some other approach that might be better?

2. I'm not sure if that surface is precision ground, but it is an adjustment interface for tilt and I feel like I want to avoid scratching it up. Would using aluminium (kitchen foil, soda can, etc) be a reasonable solution here? Thought process is that it's softer than steel and might not scratch that surface. I have access to conventional steel shim stock if that's a better plan.