I've been getting thin gouge marks occasionally and am trying to track down the cause. I believe its from either tilting the blade or changing the angle unintentionally. Either way, it's really frustrating as I'll have a really nice surface after many passes, and then get a few gouge marks that make it look like crap. I've tried relieving the corners of the blade in case that was causing the issue, however I can still seem to replicate it. They occurr in line with the blade stroke, however seem to be much deeper and thinner than the regular cuts. Is there anything I can do to stop this from happening, or do I just need to not work so long? It seems when I first start off I'll have no problems, but as I get more tired it will happen. Or when I'm trying to do lots of roughing.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Biax gouges

- Thread starter Lucas E

- Start date

- Joined

- Mar 26, 2018

- Messages

- 2,724

As a complete novice, those look like corner gouges.

I see you have the corners rounded over. On a practice piece, can you still get the corners to cut? They might need a more aggressive rounding, especially blending them into the flat bottom face.

I found with my hand scraping, especially right when I started, I couldn't control the tilt of the blade and would hit the corners. Even with a bit of rounding there was a nice sharp cutting edge at the interface between the radius and the bottom of the blade. I have several scores on my last project that came from the corners due to this. I'd imagine it is even harder to control the roll of the blade when using a power scraper.

I see you have the corners rounded over. On a practice piece, can you still get the corners to cut? They might need a more aggressive rounding, especially blending them into the flat bottom face.

I found with my hand scraping, especially right when I started, I couldn't control the tilt of the blade and would hit the corners. Even with a bit of rounding there was a nice sharp cutting edge at the interface between the radius and the bottom of the blade. I have several scores on my last project that came from the corners due to this. I'd imagine it is even harder to control the roll of the blade when using a power scraper.

- Joined

- Sep 20, 2020

- Messages

- 347

if you improperly sharpen the blade the carbide will get micro fractures but I haven't seen that before. wait to see what Richard King says or someone a lot more knowledgeable than me.

I too feel like it's corner gouges. I'm wondering if there's something more I can do to the blade to help prevent it. I could grind more, but I'm leary of going too nuts on a brand new expensive biax blade unless someone with more experience recommends it. If it's simply a matter of technique and paying attention to not roll the blade then I'm doomed. I'm too ADD to pay close attention for that long of a time.As a complete novice, those look like corner gouges.

I see you have the corners rounded over. On a practice piece, can you still get the corners to cut? They might need a more aggressive rounding, especially blending them into the flat bottom face.

I found with my hand scraping, especially right when I started, I couldn't control the tilt of the blade and would hit the corners. Even with a bit of rounding there was a nice sharp cutting edge at the interface between the radius and the bottom of the blade. I have several scores on my last project that came from the corners due to this. I'd imagine it is even harder to control the roll of the blade when using a power scraper.

- Joined

- Mar 26, 2018

- Messages

- 2,724

I'd wait to see if some of the more experienced scraping guys on here can give you some advice, but my suggestion would be to develop the rounding on the corners until it is fully blended into the flat surface. Grab a scrap piece of any material and prove to yourself that the corners cannot cut at all, only glide over the surface.I too feel like it's corner gouges. I'm wondering if there's something more I can do to the blade to help prevent it. I could grind more, but I'm leary of going too nuts on a brand new expensive biax blade unless someone with more experience recommends it. If it's simply a matter of technique and paying attention to not roll the blade then I'm doomed. I'm too ADD to pay close attention for that long of a time.

Gotta say though, as best I can tell from the somewhat blurry picture, the corners on your scraper look nicely rounded.

- Joined

- Feb 1, 2018

- Messages

- 1,868

The problems could be from a few issues. You need to hold the scraper tight against your body and swivel on your ball of your feet. I say like your doing the dance "twist" or a hulu - hoop....lol.... Then practice doing short movements at first say 1" long and in the 1 inch you scrape 4 or 5 individual low spots. If you look at the several photo's I added to the post about hand scraping there is a picture of a scraper with a folded business card taped to it. That is what I call a flag and it gives you a visual vertical display you can watch so you keep it flat and not scratch. I had a student think that up as he was scratching all the time and I tried everything I could think of with no success.

See the scraper is held horizontal and up a bit in the back so your blade is in the center of the tip radius. If you hold it wrong as Peter Ross - first picture the blade corners are closer to the edges and a slight roll and bingo...you scratch. Hold the scraper as if your holding a puppy. It lays on the top of your arm. I started using a BIAX in 1972, so I figured out how to use them. If someone says they don't scratch they are a liar. I even get one once in a while.

You have to grind the blade tip to a 60 mm radius or 2 1/2" . The blades come to flat and if you don't hold the scraper against your body to stabilize it you move your arms and bingo you scratch. If your blade is dull you roll it to cut on the edge and bingo you scratch. I also teach the students to divide the test bar up in 3 long sections and scrape 3 or for low spots and pick it up before scraping the next section. One has to practice holding the scraper blade flat and when lifting it you go straight up and not twist it . I have the students practice these moves for a couple of hours before we blue the parts up.

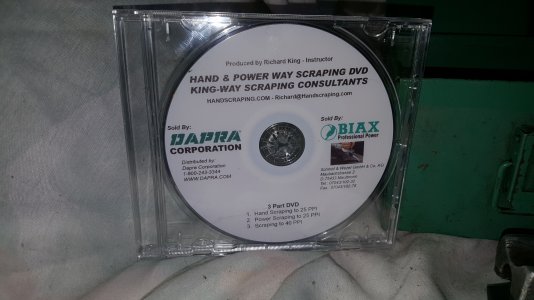

Pic: Famous Blacksmith Peter Ross holding the scraper. Famous You Tuber Keith Rucker holding the scraper. Student holding scraper tight against his body. left elbow touching his side. You tuck the scraper back so your looking straight down at what your scraping. Do the twist with body and not your arms. I sell a DVD showing the right techniques. Or come to a class and I guarantee you will not get those terrible scratches again.

See the scraper is held horizontal and up a bit in the back so your blade is in the center of the tip radius. If you hold it wrong as Peter Ross - first picture the blade corners are closer to the edges and a slight roll and bingo...you scratch. Hold the scraper as if your holding a puppy. It lays on the top of your arm. I started using a BIAX in 1972, so I figured out how to use them. If someone says they don't scratch they are a liar. I even get one once in a while.

You have to grind the blade tip to a 60 mm radius or 2 1/2" . The blades come to flat and if you don't hold the scraper against your body to stabilize it you move your arms and bingo you scratch. If your blade is dull you roll it to cut on the edge and bingo you scratch. I also teach the students to divide the test bar up in 3 long sections and scrape 3 or for low spots and pick it up before scraping the next section. One has to practice holding the scraper blade flat and when lifting it you go straight up and not twist it . I have the students practice these moves for a couple of hours before we blue the parts up.

Pic: Famous Blacksmith Peter Ross holding the scraper. Famous You Tuber Keith Rucker holding the scraper. Student holding scraper tight against his body. left elbow touching his side. You tuck the scraper back so your looking straight down at what your scraping. Do the twist with body and not your arms. I sell a DVD showing the right techniques. Or come to a class and I guarantee you will not get those terrible scratches again.

Attachments

Last edited:

- Joined

- Feb 1, 2018

- Messages

- 1,868

Oh It looks like you made a Home made blade. How long is it? Save some problems and buy a 30 ( 1 1/4") or 25 mm (1") wide x 150 mm (6") wide blade from DAPRA 1-800 243 3344 and when you get it grind it to a 60 mm radius ( 2 1/2"). Your blade looks like a 90 mm rad. ( 3 1/2") to flat for a rookie.

Thanks for the advice richard. I'd love to take a class. I'm in Oklahoma City and will be watching out for when you offer one around this area. Dallas, wichita, kansas city, etc. Are all reasonable driving distances. I'm trying to avoid having to get on a plane or take off any more time from work than necessary.

That's a biax 20-150 I got from Ed Dyjack. I just ran the corners across the slow speed grinder with a 3000 grit wheel to take off the sharp point.

I didn't even think to measure the radius, I just assumed those came with 60mm. I'll definitely shape it to 60mm If it's not.

That's a biax 20-150 I got from Ed Dyjack. I just ran the corners across the slow speed grinder with a 3000 grit wheel to take off the sharp point.

I didn't even think to measure the radius, I just assumed those came with 60mm. I'll definitely shape it to 60mm If it's not.

It is indeed a 60mm radius. Guess I just need to practice paying more attention. Its usually not as bad as in the picture I posted. I was being lazy and roughing super fast when that happened. Mostly it's just 2-3 deep scratches near a corner.Thanks for the advice richard. I'd love to take a class. I'm in Oklahoma City and will be watching out for when you offer one around this area. Dallas, wichita, kansas city, etc. Are all reasonable driving distances. I'm trying to avoid having to get on a plane or take off any more time from work than necessary.

That's a biax 20-150 I got from Ed Dyjack. I just ran the corners across the slow speed grinder with a 3000 grit wheel to take off the sharp point.

I didn't even think to measure the radius, I just assumed those came with 60mm. I'll definitely shape it to 60mm If it's not.

Attachments

- Joined

- Feb 1, 2018

- Messages

- 1,868

Every couple of years I teach a class at J&S Machine and Valve in Nowata, OK. He has me show his guys to scrape and test straightness. . If im still breathing in 2 years....I'll advertise the class in my forum . I also have a Facebook forum I write a lot about scraping and rebuilding. It's listed under my company Name. King-Way Scraping Consultants. We have around 800 members now and there are around 6 pro's and several are my students. I base it a lot like this forum, NO BS or you get kicked out. That's what makes Hobby Machinist forum so good. Nelson did a great service to our industry forming this forum. I pray he is still reading and healthy. Rich....PS. Next time you talk to Ed say HI. I've known Ed Dyjak for 30 years. His Dad, Ed Senior was a service tech for Pratt & Whitney and he hand scraped. When he retired he started to sell rebuilding tools.