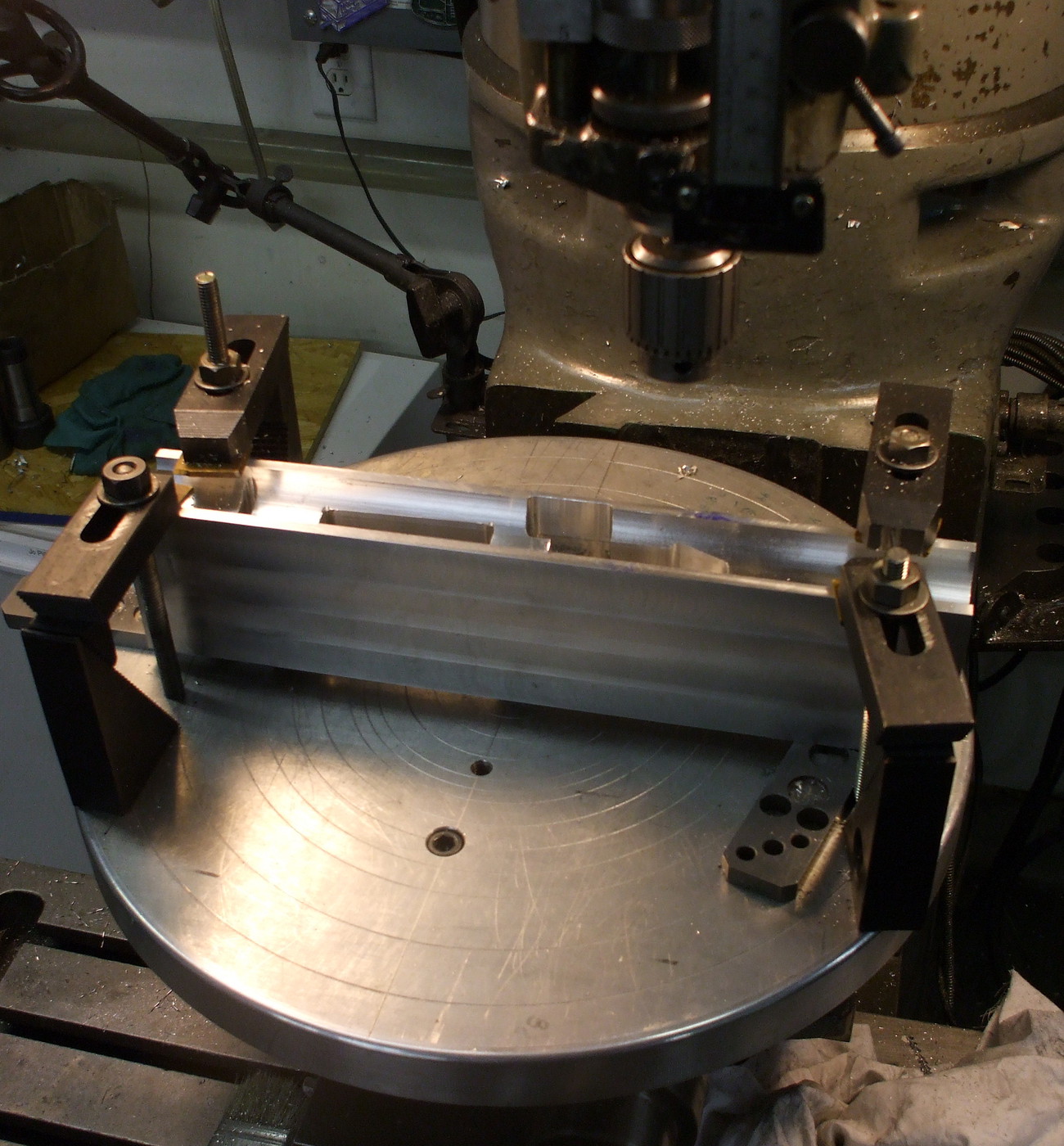

Latin, Yes, I cast it myself. 1 1/8" particle board pattern, alloy car wheel and some disc drive cases, propane fired, home made (by someone else) melt furnace, sand mold.

Alloy wheels are some pretty good metal. For any of you wanting to do your own casting, Olfoundryman on YouTube has excellent videos. I bought my furnace for $40, complete with fan, gages, & hoses. I bought a #16 graphite/clay crucible. I tried melting copper but it wouldn't get hot enough. So next project is building a better furnace & firing on used oil or diesel.