- Joined

- Feb 3, 2014

- Messages

- 39

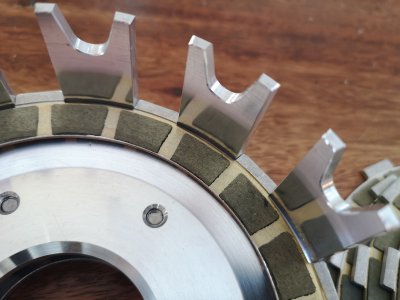

Some of the pates (about half) have projections that engage the basket. There will be significant force between those pates and the basket. The other pates will have splines that engage the shaft.

Actually not significant at all.

Torque at crank is 70 Nm (read off of dyno chart). Primary ratio is 2.41 (65/27).

Torque at clutch is then 70 Nm * 2.41 = 168.7 Nm

Distance from center to tabs (radius): r = 68 mm = 0,068 m

Tangential force at tabs (total): F= T/r = 168.7 Mn / 0,068 m = 2481.9 N

Thickness of tabs: 2.5 mm

Engagement with basket: 3.5 mm

Number og tabs per friction plate: 12

Number of friction plates: 7

Total surface area: A = 2.5 mm * 3.5 mm * 12 * 7 = 735 mm²

Surface pressure: P = F/A = 2480.9 N / 735 mm² = 3.38 N/mm² (3.38 MPa)

Compare that to the yield strength of 7075-T6 aluminum which could be around 500 MPa

Wear on the clutch basket from the friction plate tabs is not caused by excessive pressure.

It is abrasive wear cased by vibrations, which again is very small due to this being a wet clutch.