- Joined

- Jun 30, 2015

- Messages

- 143

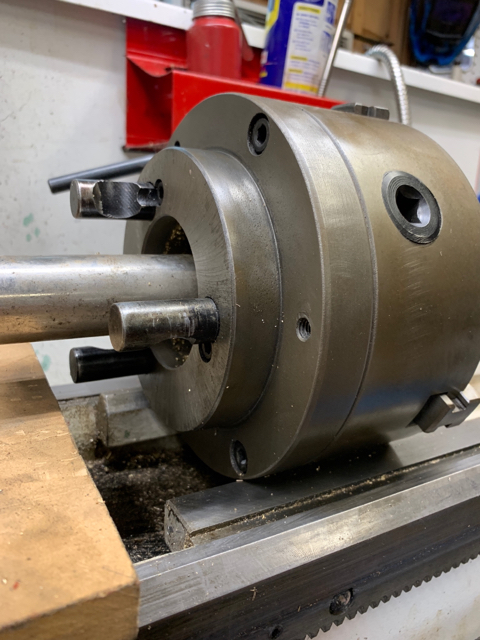

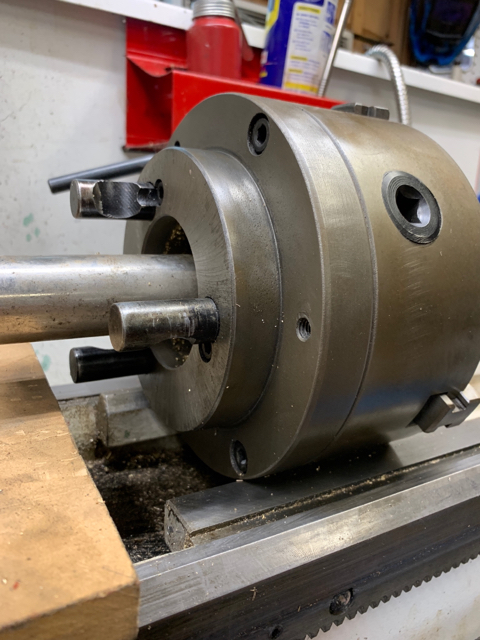

My Chinese chuck back plates have d1-4 adaptor with only 3 studs

I will be buying a Bison 6 jaw 6” set tru chuck but the only adaptor plate that they offer has 6 studs

Model number for d1-4 adaptor plate is 7-875-064

How do I fit the square into the circle. What am I missing

Sent from my iPhone using Tapatalk

I will be buying a Bison 6 jaw 6” set tru chuck but the only adaptor plate that they offer has 6 studs

Model number for d1-4 adaptor plate is 7-875-064

How do I fit the square into the circle. What am I missing

Sent from my iPhone using Tapatalk