The boat is finally on the trailer but unfortunately, I cracked the windscreen when I was positioning it, I had been jacking the boat up and down all day getting the rollers in the right place and the last lift of the day, I was very tired and just forgot to check how close it was to the garage roof beam. Not happy, there goes another couple of hundred bucks out the window,( excuse the pun) anyway it is position now, to top it off I have also torn a ligament or muscle in my shoulder from manoeuvring and positioning the 12 ton bottle jack under the boat all day, so that has slowed me down a little and it is quite painful.

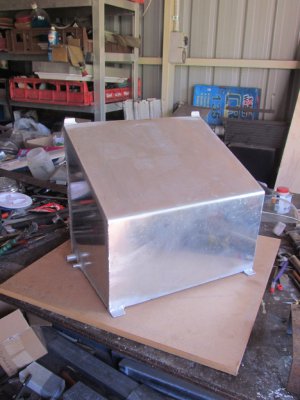

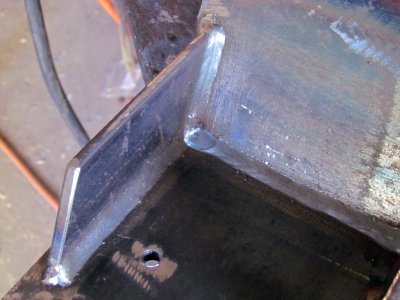

I have just about finished off the trailer, made a bracket to hold the spare wheel on the winch post, had to modify and move the winch back another 200mm to move the boat forward a bit more as it was a bit too light on the draw bar, putting the wheel on the anchor post will also help to increase the weight on the drawbar, originally planned to put it underneath the boat at the start of the walkway, but that space is now available for a tool/rope box that I will make (much later), made 3 sets of double keel roller brackets to add more support for the boats keel and only need to make a bracket to hold the vee block for the bow of the boat and that's the trailer done. It now has 32 wobble rollers and 6 keel rollers under the boat.

I have just about finished off the trailer, made a bracket to hold the spare wheel on the winch post, had to modify and move the winch back another 200mm to move the boat forward a bit more as it was a bit too light on the draw bar, putting the wheel on the anchor post will also help to increase the weight on the drawbar, originally planned to put it underneath the boat at the start of the walkway, but that space is now available for a tool/rope box that I will make (much later), made 3 sets of double keel roller brackets to add more support for the boats keel and only need to make a bracket to hold the vee block for the bow of the boat and that's the trailer done. It now has 32 wobble rollers and 6 keel rollers under the boat.