- Joined

- Aug 20, 2018

- Messages

- 219

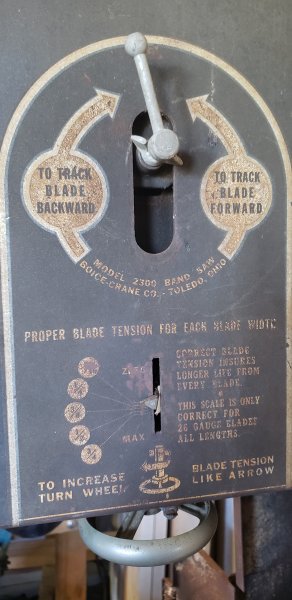

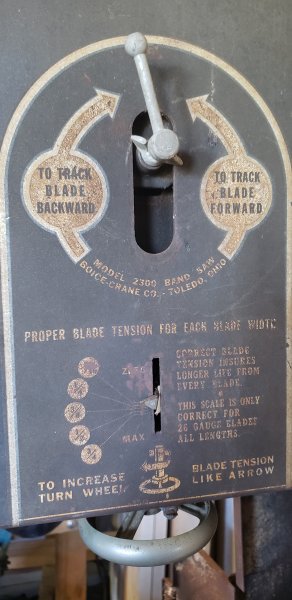

Going to post my progress, this far, on my Boice Crane vertical bandsaw restoration and metal conversion. Some of this is already posted in the POTD thread, but I'd like to have a spot to post from beginning to the end. I picked up this bad boy from an older gentleman, on Craigslist, for $25. He had it stored outside, on his driveway, under a tarp, for only him and God know how long.

So first, some pics of original condition...

So first, some pics of original condition...