- Joined

- Jan 1, 2014

- Messages

- 233

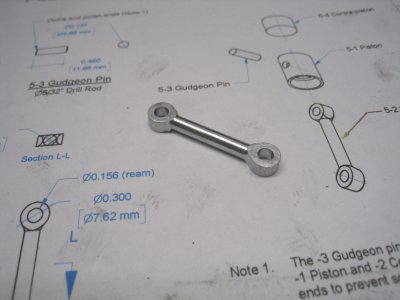

Am looking at the BollAero 18 diesel as my next model engine project. Have been studying the plans and have a question I hope an H-M member familiar with the BollAero 18 might answer. It has to do with the placement of the transfer ports in the cylinder sleeve (page 6 of the drawing set) which are 45 degrees each side of the exhaust port (90 degrees apart). I know the transfer ports allow the pressurized charge from the crankcase to the cylinder when the piston is at a certain point. In other words transfer is based on vertical movement of the piston (timing) and not on where the ports are in the horizontal. As designed the cutouts for the transfer ports are pretty close to the exhaust port making sealing the crankcase a little more problematic. I can't isolate that portion out of the blueprints so hope someone can understand and answer from my description.

Can the transfer ports be spaced 180 degrees apart thus 90 degrees from both the intake and exhaust ports?

Can the transfer ports be spaced 180 degrees apart thus 90 degrees from both the intake and exhaust ports?

Last edited: