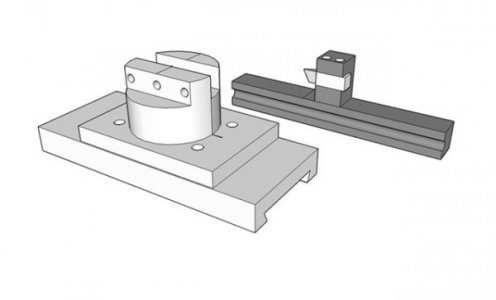

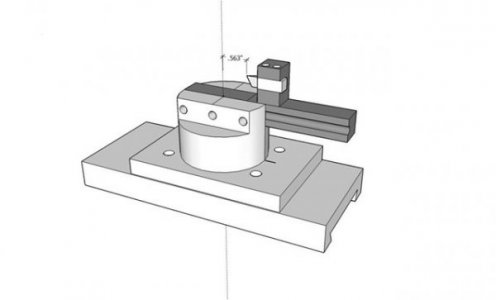

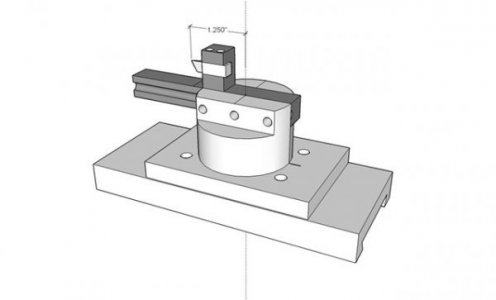

If I understand the drawing correctly you plan on holding a tool in the slot and rotating it to form a radius on the part?

Or is there a tool holder attachment that fits in the slot that will allow you to make both concave and convex radii.

Or is there a tool holder attachment that fits in the slot that will allow you to make both concave and convex radii.