-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Boring bar offset

- Thread starter ARC-170

- Start date

- Joined

- Mar 3, 2017

- Messages

- 744

Tungsten carbide is available sintered with cobalt as binder, for cutting tools; that's "solid carbide" in mostWhat, if any is the difference between tungsten carbide or tungsten steel and solid carbide? I'm looking for the most rigid bar as in the 3rd paragraph of post #6.

advertising material. Tungsten steel is a good knife-making alloy. For machining, vanadium and cobalt

are used/advertised as enhancements (high speed steel) over regular old steel.

The classic boring bar is regular steel (good and strong, but not necessarily at high temperatures) with

a HSS or carbide tip. Solid carbide boring bars are supposedly more stiff than steel (but are brittle,

will break rather than bend).

Chinese-after-translation might call 'tungsten' or 'tungsten steel' meaning solid carbide.

.... like here AliExpress sells carbide

which looks like carbide, called carbide, but is also called 'hard alloy tungsten steel' in the description...

- Joined

- Dec 20, 2012

- Messages

- 9,422

What, if any is the difference between tungsten carbide or tungsten steel and solid carbide? I'm looking for the most rigid bar as in the 3rd paragraph of post #6.

Thanks

Aaron

Aaron, I took a look at ebay for a good 3/8" used carbide bar and found nothing. Then I looked for new ones from makers I trust and found almost nothing in the 3/8" size. There is one SCLCR bar from Seco listed that takes CCMT and/or CCGT inserts but it is a bit spendy at just over $200.00. Still, when you consider that this bar probably will bore almost any hole you might need that is around 1/2" ID and larger and up to about 3.75" deep, that price is not that bad. If you use a good bar holder, are careful when you use it and don't crash it into the bottom of a blind bore it will likely outlast you.

Plus, the inserts this bar uses are pretty cheap and should be available from ebay or more importantly, reputable sellers. Ask @davidpbest for trusted sellers; he will know. If you buy a decent bar like that Seco then authentic Seco/Iscar/Kennametal/Valenite/Mitsubishi/Sumitomo inserts will likely fit the bar. HIgh quality inserts will last far longer than cheap knock-off inserts from ebay. I have some Circle Machine inserts that are going on 10 years - same insert in the same bar, same tip! The key to longevity is to get the speeds close to the recommended speeds if you can, then get the feed fast enough to produced coiled chips and that insert will not only last; it will cut accurately.

The advantages of an SCLCR bar is that they take the readily available CCMT (most steels)and CCGT (Aluminum cutting) inserts and they are a positive lead bar that are better for blind bottom bores but also work well for through bores. These inserts also come with nose radii that are useful: 25.50 (0.004" nose radius) and 25.55 (0.008" nose radius). I would not go with larger nose radii because radial forces climb with larger nose radii. Do NOT get fooled by prices; focus on the right nose radius for boring if accuracy matters to you.

I'm surprised at the slim pickings on ebay. I used to be able to find any kind of bar I wanted with little trouble. Now, not so much. Used to have a decent selection of Circle Machine bars, too. Now, I see very few that I would choose. Not sure what is going on. It might just be that I picked the wrong night to go looking, maybe?

In any case, consider that Seco bar if you can afford it. Or wait and watch ebay for the bars I listed in my Primer; they are, by far, the best bars I own. If I could only have two of them, I would choose the Circle Machine CCBI 250 (1/4" OD)-4 or 6 (inches long)-5R (-5 degree positive lead, right handed) and a CM QCMI-375-6-5R. This gives you 2.5" depth capacity for holes under 5/16"ID or so, and almost4" deep for holes about 1/2" or bigger. That covers most holes we will bore in a hobby shop.

Hope this helps.

- Joined

- Aug 26, 2013

- Messages

- 1,061

@mikey

Shars, zoro and a few others sell Ultra-dex solid carbide bars that I have heard good things about.

~ $180 https://www.shars.com/3-8-x-6-right-hand-carbide-boring-bar-min-bore-0-41-for-ccmt-21-51-inserts

I just purchased a few bars from Maritool, as I've purchased collets form them in the past and they are well known for tool holders.

~ $107 https://www.maritool.com/Indexable-...LID-CARBIDE-BORING-BAR-.375/product_info.html

I'll post a few photos in a little bit.

Shars, zoro and a few others sell Ultra-dex solid carbide bars that I have heard good things about.

~ $180 https://www.shars.com/3-8-x-6-right-hand-carbide-boring-bar-min-bore-0-41-for-ccmt-21-51-inserts

I just purchased a few bars from Maritool, as I've purchased collets form them in the past and they are well known for tool holders.

~ $107 https://www.maritool.com/Indexable-...LID-CARBIDE-BORING-BAR-.375/product_info.html

I'll post a few photos in a little bit.

- Joined

- Dec 20, 2012

- Messages

- 9,422

Thanks, Dan. I know Maritools makes good stuff but haven't tried their boring bars yet. I like the angled joint, though.@mikey

Shars, zoro and a few others sell Ultra-dex solid carbide bars that I have heard good things about.

~ $180 https://www.shars.com/3-8-x-6-right-hand-carbide-boring-bar-min-bore-0-41-for-ccmt-21-51-inserts

I just purchased a few bars from Maritool, as I've purchased collets form them in the past and they are well known for tool holders.

~ $107 https://www.maritool.com/Indexable-...LID-CARBIDE-BORING-BAR-.375/product_info.html

I'll post a few photos in a little bit.

A key thing is the fit of the insert in the pocket. If Ultradex and Maritools accept industry standard inserts then they should be okay. My experience has been that the insert fit can be a real issue in cheap bars.

- Joined

- Aug 26, 2013

- Messages

- 1,061

A key thing is the fit of the insert in the pocket. If Ultradex and Maritools accept industry standard inserts then they should be okay. My experience has been that the insert fit can be a real issue in cheap bars.

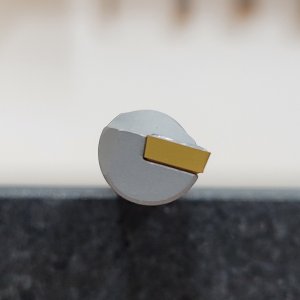

The fit is good, as seen here with my favorite sandvik 21.51 finishing inserts.

The tip of the insert is roughly 20 to 25 thousands below the centerline on the 3/8" bar. This looks to be as designed as the head protrudes downard (3rd photo).

- Joined

- Dec 20, 2012

- Messages

- 9,422

The screw needs to pull the insert into the corner so that it will be impossible for the insert to move. If that is the fit you're getting then it's good.

My personal experience with negative rake tooling like your bar is that they cut with much higher tangential cutting forces and that makes precision boring more difficult. A neutral rake tool cuts with significantly lower forces that you can feel.

I also prefer nose radii no larger than 0.008" to keep radial forces under control.

Different strokes and all that. What works for you is what works for you.

My personal experience with negative rake tooling like your bar is that they cut with much higher tangential cutting forces and that makes precision boring more difficult. A neutral rake tool cuts with significantly lower forces that you can feel.

I also prefer nose radii no larger than 0.008" to keep radial forces under control.

Different strokes and all that. What works for you is what works for you.

Last edited:

When I was first setting up and tiptoeing in, I followed @mikey advice in his Primer exactly and bought the aloris 4D, the boring bar holders, and a small Micro100 solid bar, and one of my first projects was making a sleeve. I've used them all, and nothing else, and the only times I've had trouble have been due to my operating error.

Tim

Tim