- Joined

- Oct 11, 2019

- Messages

- 16

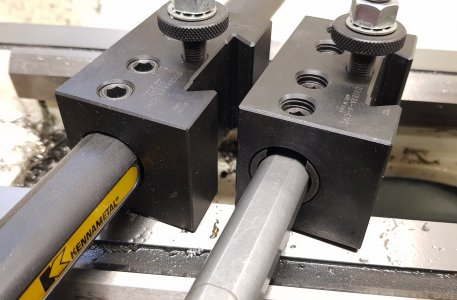

Hi, I just upgraded from a Chinese mini lathe to a craftsman industrial 12”. I tried to use my 1/4 boring bars on a project on my mini lathe and it was a night mare. That’s why I upgraded to this nice lathe. I just bought a axa qctp and am working on installing it on my craftsman. It has the 5/8” holder for it. Do I need to buy a new set or can I somehow use my old (new) ones. Please advise.