- Joined

- Dec 30, 2017

- Messages

- 117

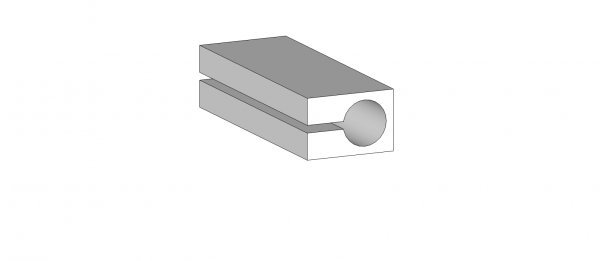

I understand the concept of boring bars. I have searched for all the videos I can think of concerning boring bars. I now have a "need" for a boring bar setup. I have shopped on Amazon, eBay, Shars, Grizzly, etc. for boring bars, but nowhere can I find someone who explains how to hold the thing in a four-way toolpost, or where to buy such a toolholder! I've got to be missing something.

Does anyone have a link to a video I can watch about this? Is it absolutely impossible to hold a boring bar in anything but a quick change toolpost or a lantern style toolpost? Do I clamp it down in the four-way without a holder? Is there something special that a boring bar holder is called for a four-way?

I've got to be missing a piece of the puzzle. Any help is appreciated!

Does anyone have a link to a video I can watch about this? Is it absolutely impossible to hold a boring bar in anything but a quick change toolpost or a lantern style toolpost? Do I clamp it down in the four-way without a holder? Is there something special that a boring bar holder is called for a four-way?

I've got to be missing a piece of the puzzle. Any help is appreciated!