- Joined

- Nov 27, 2012

- Messages

- 7,852

1.34", that would be BXA territory (or 250-200 series for the Asian imports). Sounds like you have a 12"-14" lathe.

Bolt on out of the box, unfortunately no unless they sell one specifically for your model lathe. QCTPs usually come with blank t-nuts & you have to machine them to fit. There are so many different lathes out there all with different t-slot sizes so the t-nuts come blank.

If you don't have access to a mill there are ways to make t-nut using the lathe. I'm sure you could find help here to get it mill it for you.

www.hobby-machinist.com

www.hobby-machinist.com

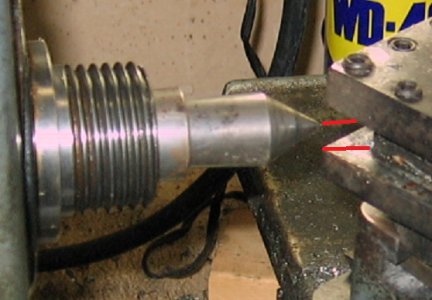

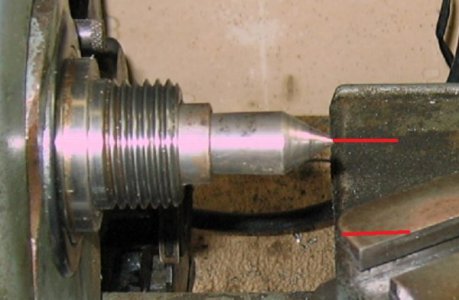

A couple of more examples from the net. I do remember seeing someone selling QCTPs 9n ebay with premachined t-nuts like these but that was a long time ago & don't remember the details.

I looked at the ones from Shars (so I could start drooling for when the funds arrive) and it looks like they come with their own t-slot that I will need to machine to fit. Obviously I'd prefer to be lazy, as my mill is kinda "down" right now, so I'd prefer to get away with no milling. Is there any chance that the bolt to hold the Aloris style holder will be the same as what I've got on it right now?

Bolt on out of the box, unfortunately no unless they sell one specifically for your model lathe. QCTPs usually come with blank t-nuts & you have to machine them to fit. There are so many different lathes out there all with different t-slot sizes so the t-nuts come blank.

If you don't have access to a mill there are ways to make t-nut using the lathe. I'm sure you could find help here to get it mill it for you.

How do YOU make a "T" nut for your QCTP?

You buy a new QCTP and it comes with an oversize "T" nut that you have to mill to size. How do you do it? (Photos if possible). How do you measure the correct dimensions of the T-slots, set up the job on the milling machine or other machine that you use, and remove the excess material. This is...

www.hobby-machinist.com

www.hobby-machinist.com

A couple of more examples from the net. I do remember seeing someone selling QCTPs 9n ebay with premachined t-nuts like these but that was a long time ago & don't remember the details.