I don't know if this is the place to post this, but I bet a lot of folks could use this simple idea. My Burke mill is great but I needed something bigger now and then. This is how you can turn your lathe into a horizontal boring mill.

I made a milling table for my lathe using a ground plate I bought on ebay. I drilled and tapped a pattern of holes for clamping work. It is held in place by a center plug that fits in place of the compound.

This is the easy to make table. Cost me $30

This is the easy to make table. Cost me $30

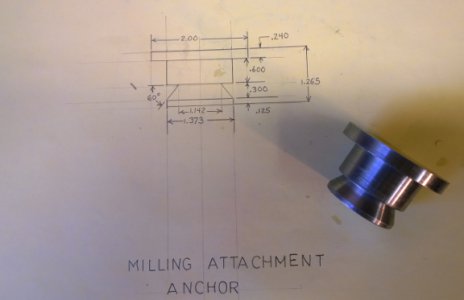

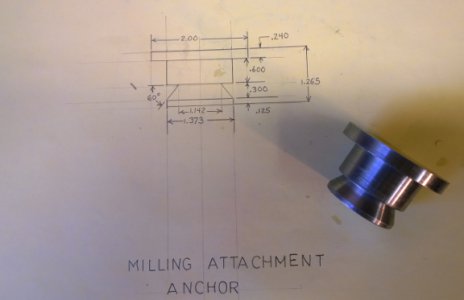

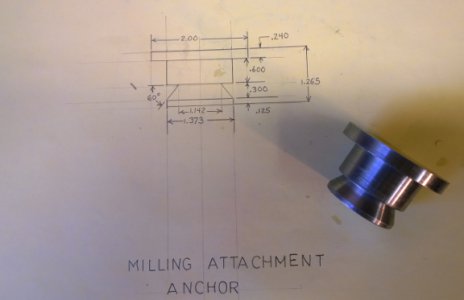

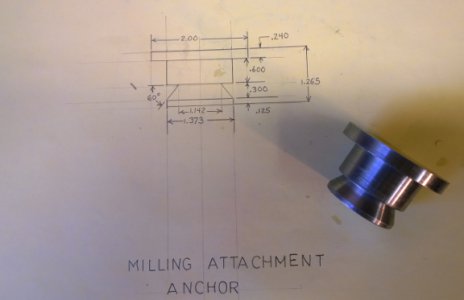

This is the print and the anchoring plug for the table. This is a very sturdy setup. You can see it in use in my steady rest thread.

This is the print and the anchoring plug for the table. This is a very sturdy setup. You can see it in use in my steady rest thread.

This is the table installed on my lathe.

This is the table installed on my lathe.

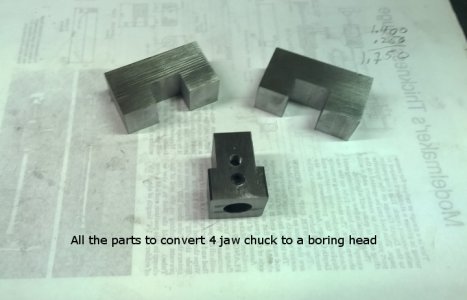

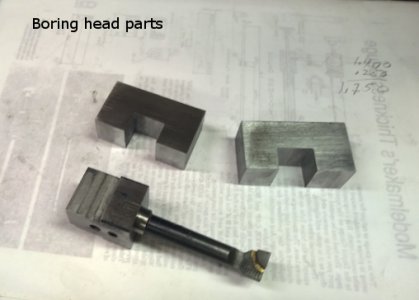

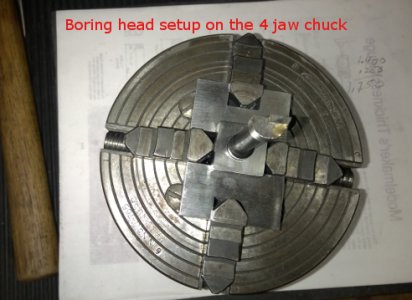

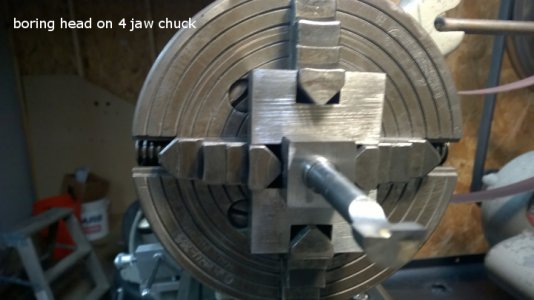

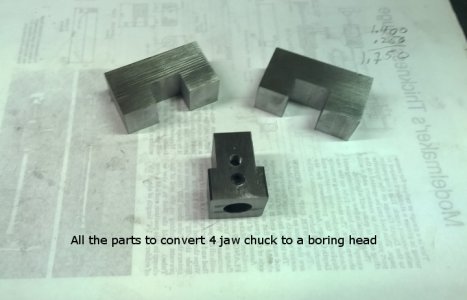

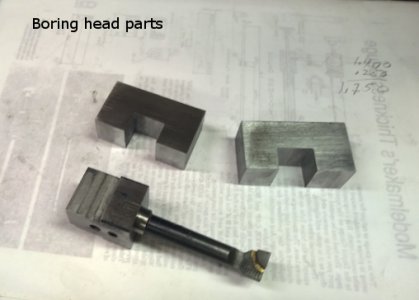

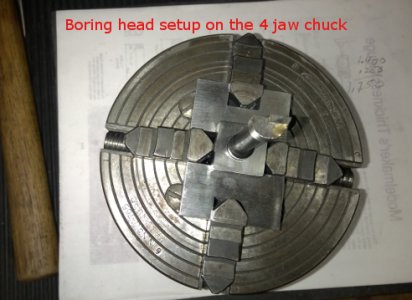

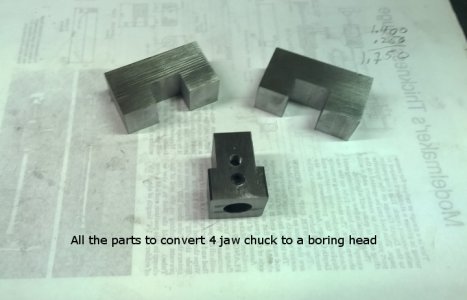

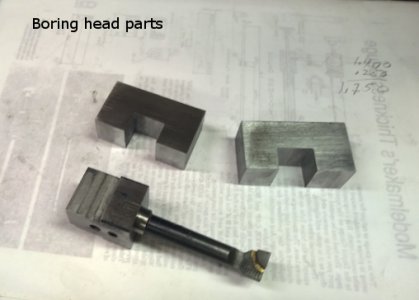

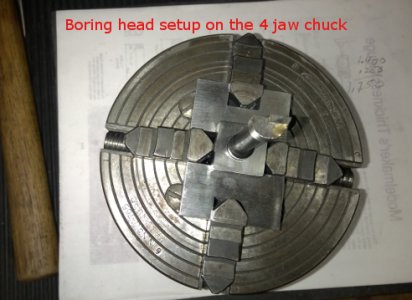

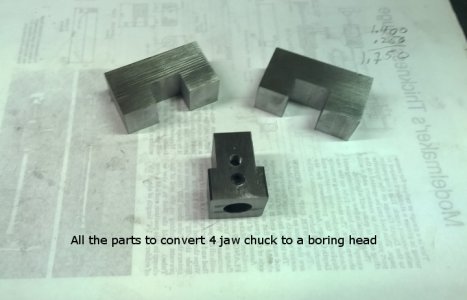

Now for the boring head. Make these three parts and convert you 4 jaw chuck into an adjustable boring head.

Got your interest?

Got your interest?

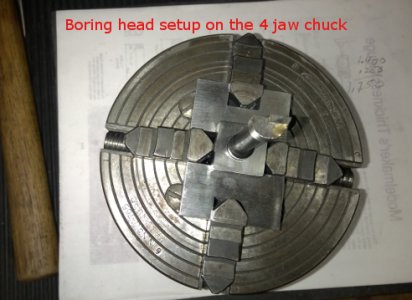

Figured it out yet?

Figured it out yet?

:thinking:

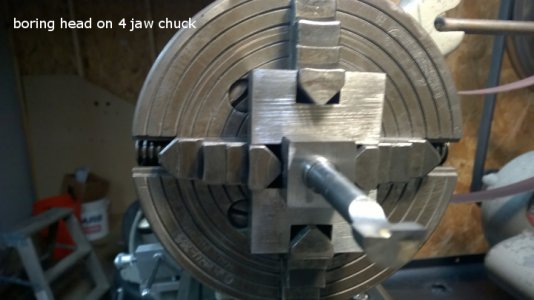

These three little parts turn your four jaw chuck into an adjustable precision boring head and it works great because I used it to bore the three holes in my steady rest to perfect size within .0005"

These three little parts turn your four jaw chuck into an adjustable precision boring head and it works great because I used it to bore the three holes in my steady rest to perfect size within .0005"

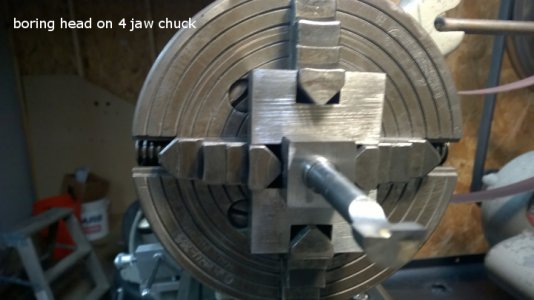

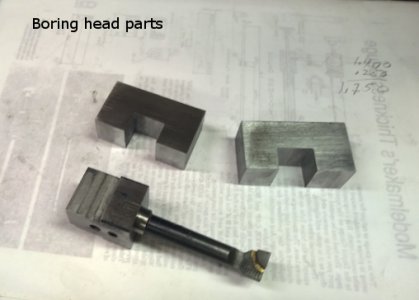

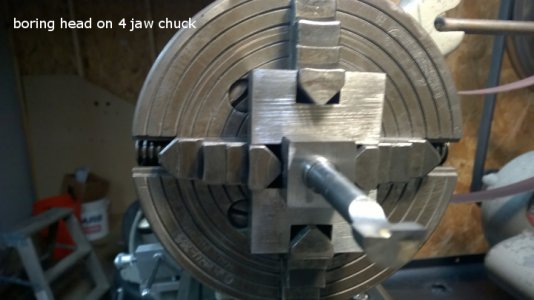

I am going to draw a print for this but the ALL the dimensions have to be altered to match YOUR chuck if you make this. The notch in the two side supports must be the same width as the jaws on the chuck and be deep enough to catch the sides of the jaws. The block to hold the boring bar is 1 inch square and has a .500" hole for the boring bars. The width of the block below the steps must be the same width exactly as the jaws on the chuck. The two jaws holding the notched blocks tighten against the boring bar block but since they are the same width it is a tight hold but still can slide with some force. The other two jaws tighten against the boring bar block, locking it in position. To adjust the bar you loosen one side and tighten the other. You can change the setting by a small amount( .0005 - .001") by merely putting a little more pressure on one jaw without touching the other one. I hope I have explained this well enough. This is a simple device and took me an hour to make. This and the milling table combined turn you lathe into a horizontal boring mill.

Mark

I made a milling table for my lathe using a ground plate I bought on ebay. I drilled and tapped a pattern of holes for clamping work. It is held in place by a center plug that fits in place of the compound.

This is the easy to make table. Cost me $30

This is the easy to make table. Cost me $30 This is the print and the anchoring plug for the table. This is a very sturdy setup. You can see it in use in my steady rest thread.

This is the print and the anchoring plug for the table. This is a very sturdy setup. You can see it in use in my steady rest thread. This is the table installed on my lathe.

This is the table installed on my lathe.Now for the boring head. Make these three parts and convert you 4 jaw chuck into an adjustable boring head.

Got your interest?

Got your interest? Figured it out yet?

Figured it out yet?:thinking:

These three little parts turn your four jaw chuck into an adjustable precision boring head and it works great because I used it to bore the three holes in my steady rest to perfect size within .0005"

These three little parts turn your four jaw chuck into an adjustable precision boring head and it works great because I used it to bore the three holes in my steady rest to perfect size within .0005"I am going to draw a print for this but the ALL the dimensions have to be altered to match YOUR chuck if you make this. The notch in the two side supports must be the same width as the jaws on the chuck and be deep enough to catch the sides of the jaws. The block to hold the boring bar is 1 inch square and has a .500" hole for the boring bars. The width of the block below the steps must be the same width exactly as the jaws on the chuck. The two jaws holding the notched blocks tighten against the boring bar block but since they are the same width it is a tight hold but still can slide with some force. The other two jaws tighten against the boring bar block, locking it in position. To adjust the bar you loosen one side and tighten the other. You can change the setting by a small amount( .0005 - .001") by merely putting a little more pressure on one jaw without touching the other one. I hope I have explained this well enough. This is a simple device and took me an hour to make. This and the milling table combined turn you lathe into a horizontal boring mill.

Mark