- Joined

- Mar 26, 2018

- Messages

- 8,398

I have yet to be able to bore with this mill. It’s not the mill. I have a 30 taper, I can use the ER40 chuck or the 30 taper holder.

I must be missing something.

I have way too much flex with my options available.

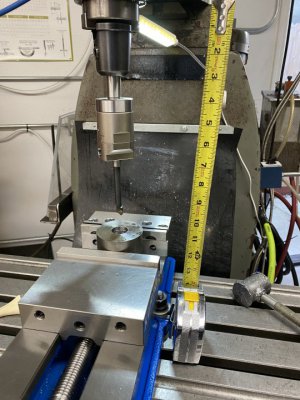

The best I can do is 8” with a short Criterion bar To the spindle lugs.

The boring head is a 2” Shars. The table is locked, the quill is locked, the gibs on the boring bar are tight.

Ideas? I can make this thing sing big time with terrible results.

Heck, my wore out BP with an R8 did a better job.

I must be missing something.

I have way too much flex with my options available.

The best I can do is 8” with a short Criterion bar To the spindle lugs.

The boring head is a 2” Shars. The table is locked, the quill is locked, the gibs on the boring bar are tight.

Ideas? I can make this thing sing big time with terrible results.

Heck, my wore out BP with an R8 did a better job.