- Joined

- Nov 9, 2018

- Messages

- 377

BTDT and trying to use that type hoist, when the boom was extended full length, it no longer had the lift capacity to pick my lathe. That hoist is also unstable when the boom is extended to the max. Your results may vary.Back truck into garage, lift lathe engine hoist from rear of truck, drive truck out, slowly lower lathe to ground

I agree, that hoist is OK for most of the stuff I work on (vintage Datsuns and VWs), but is unstable AF moving machine tools.BTDT and trying to use that type hoist, when the boom was extended full length, it no longer had the lift capacity to pick my lathe. That hoist is also unstable when the boom is extended to the max. Your results may vary.

jack vines

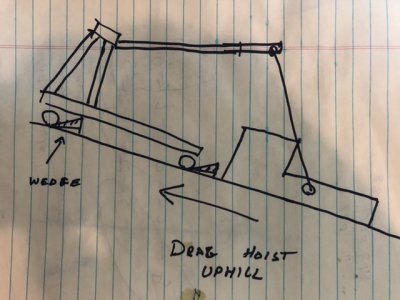

That’s a great idea. Your idea just inspired a variation of it, where you can put the item on the ground, looses up the straps, push hoist uphill, wedge the hoist and lift, this should inch and drag the item uphill.Lift it with the hoist and drive the truck out from underneath it, then let the hoist down.

A neat trick with the hoist on gradients is to lift the machine just off the floor, push it uphill as far as the straps will permit (longer straps help here), let it down, reposition and chock the hoist, raise, rinse and repeat. It's slow, but far safer than trying to roll it on the hoist.