- Joined

- Jan 7, 2016

- Messages

- 3,259

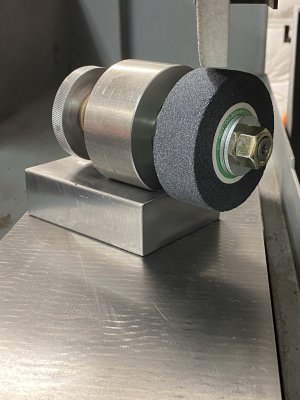

Oh weird. I am taking apart the work stations I purchased (Listed here) and I discovered that all of the steel is nickel coated. Looks just like yours in the blue light!It seems any time I take a pic on a blue shop paper towel the steel comes out with this color finish??

It is kind of cool.

I like that look!