Which way to install the nuts wouldn't be an issue if you used two nuts of the same thickness.

Which, to be honest, is what I've done in the last few years because of my peculiar zinc arrangement.

Which way to install the nuts wouldn't be an issue if you used two nuts of the same thickness.

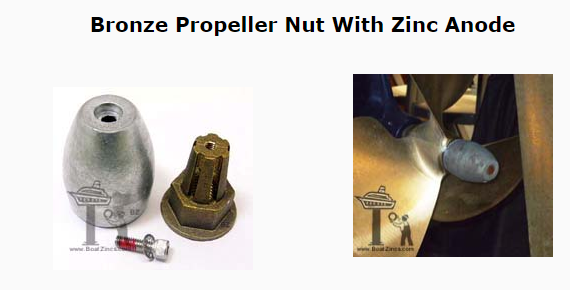

Other than the crazy price they get for them why not just use a "C" size prop nut and zinc? It's 3/4-10 thread. Typically the shaft is drilled for a cotter pin. View attachment 259535

http://www.boatzincs.com/prop_nut_s...MIkoCp8e6_2QIVxiSBCh1BtwX7EAQYASABEgL24PD_BwE