This is going to be my first CNC build and my First build log. I've decided that a build log on this forum might be a good idea for this project so the next guy to take on this project doesn't have to deal with the stupid stuff I'm already running into.

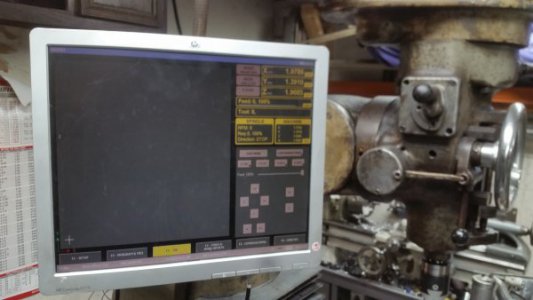

This is my Masso Controller

I will be using 3 Clearpath Stepper Killer servos model# CPM-SDSK-3432S-RLN

They are a little over 6" long...

almost 3.5"

1/2" shaft with a 3/16" keyway

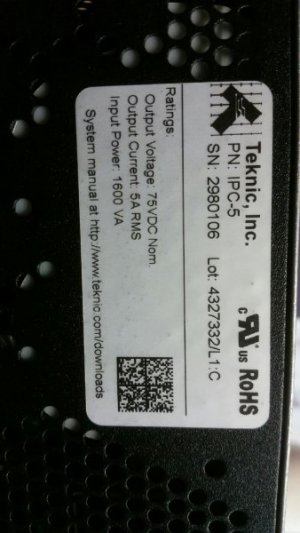

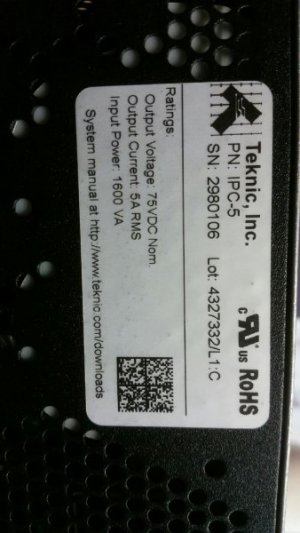

I will be using Teknic's IPC-5 75VDC power supply

But before you can wire up you Masso controller you have to power up the Clearpath servos and plug them in to a PC with the ClearPath USB-B cable and it absolutely has to be their cable I've already tried 5 others, now I'm waiting for UPS to deliver a "Teknic Certified" USB cable. Very Lame....

Their program will not see my servos without the "Teknic Certified" USB cable...

Edit: Almost any USB cable will work.... lol

This is my Masso Controller

I will be using 3 Clearpath Stepper Killer servos model# CPM-SDSK-3432S-RLN

They are a little over 6" long...

almost 3.5"

1/2" shaft with a 3/16" keyway

I will be using Teknic's IPC-5 75VDC power supply

But before you can wire up you Masso controller you have to power up the Clearpath servos and plug them in to a PC with the ClearPath USB-B cable and it absolutely has to be their cable I've already tried 5 others, now I'm waiting for UPS to deliver a "Teknic Certified" USB cable. Very Lame....

Their program will not see my servos without the "Teknic Certified" USB cable...

Edit: Almost any USB cable will work.... lol

Last edited:

![20180921_110534[1].jpg 20180921_110534[1].jpg](https://www.hobby-machinist.com/data/attachments/233/233244-5cd130cacdafc256fc8d88c2d5f382a0.jpg)