- Joined

- Mar 21, 2013

- Messages

- 4,062

I am building a 10mm, based on a 80% Jem frame and slide. I also bought the Jem GS as well. I am currently waiting on the Jem slide, and a KKM barrel. But I have the GS and a Chen MSH, so I thought I'd start at the bottom and work my way up.

The Jem GS 'almost' fit, but I needed to clean up the frame a bit on the inside as well as take a bit more off the radius to get the EGW thumb safety to go into position. The Chen MSH was not even close to slipping into the Jem frame. So out came the files and sandpaper. I'm in no real hurry on this project and I'd like to give this build a little extra effort.

Finally got the MSH to fit. It's VERY tight though, needing a little persuasion from a drift to start it out of the frame.

I liked the little mini 'round butt' I did on my Kimber, so I decided to do it to this pistol as well.

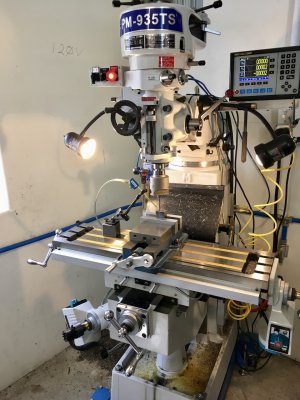

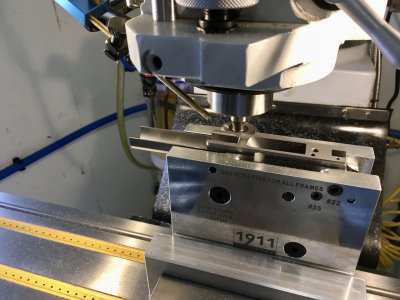

I finally made up my mind to put a mag well on this thing. And I decided to make my own this time. First thing is I need a nice flat piece of stainless, 0.300" thick.

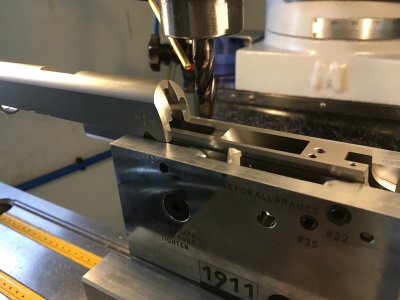

I hate face mills because they throw sharp, hot, chips half-way across my shop! I managed to cut the frame and the mag funnel without scrapping either part.

Those are grips I fitted to a different pistol, but it looks like they should work on this OK. The mag funnel piece fits nice and tight on the frame. I won't be silver soldering it on until I cut the frame rails. And I can't do that until I get the slide and get some dimensions from it.

But I'm liking it so far.

Edit: I guess I can start on the frontstrap checkering while I wait for my slide to show up.

The Jem GS 'almost' fit, but I needed to clean up the frame a bit on the inside as well as take a bit more off the radius to get the EGW thumb safety to go into position. The Chen MSH was not even close to slipping into the Jem frame. So out came the files and sandpaper. I'm in no real hurry on this project and I'd like to give this build a little extra effort.

Finally got the MSH to fit. It's VERY tight though, needing a little persuasion from a drift to start it out of the frame.

I liked the little mini 'round butt' I did on my Kimber, so I decided to do it to this pistol as well.

I finally made up my mind to put a mag well on this thing. And I decided to make my own this time. First thing is I need a nice flat piece of stainless, 0.300" thick.

I hate face mills because they throw sharp, hot, chips half-way across my shop! I managed to cut the frame and the mag funnel without scrapping either part.

Those are grips I fitted to a different pistol, but it looks like they should work on this OK. The mag funnel piece fits nice and tight on the frame. I won't be silver soldering it on until I cut the frame rails. And I can't do that until I get the slide and get some dimensions from it.

But I'm liking it so far.

Edit: I guess I can start on the frontstrap checkering while I wait for my slide to show up.

Last edited: