-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a 10mm

- Thread starter wrmiller

- Start date

- Joined

- Mar 21, 2013

- Messages

- 4,063

A friend on the 1911addicts forum told me about melonite last night. Not a too spendy hard coating that will show a polished surface.

Yea, I screwed up that upper cut on the ejector. I wanted a fully flush fit, but had a brain spasm on that upper cut I guess. Functional, but it's noticable. I have another ejector and will fix that eventually.

Yessir, I know a couple that get 5 figures for a custom 1911. I've had a few folks ask for builds, but I'm not set up for a business.

Here's a few more pics for those interested. The one on the left is my 20 year old Kimber 45 that stone cold shot a 3-shot group (standing, 10yds.) I covered with a nickel.

Yea, I screwed up that upper cut on the ejector. I wanted a fully flush fit, but had a brain spasm on that upper cut I guess. Functional, but it's noticable. I have another ejector and will fix that eventually.

You have a bad case of OCD, but your build looks very good.

edit: This is why some gunsmiths charge $$$$$, attention to detail.

Yessir, I know a couple that get 5 figures for a custom 1911. I've had a few folks ask for builds, but I'm not set up for a business.

Here's a few more pics for those interested. The one on the left is my 20 year old Kimber 45 that stone cold shot a 3-shot group (standing, 10yds.) I covered with a nickel.

- Joined

- Nov 10, 2013

- Messages

- 376

I’ve been wanting to do one for a long time I think this post sealed the deal!!!!!

@wrmiller I recently purchased two 80% 2011 frames and all the bits and pieces to build two 9mm's. I don't have a mill so I'm going to use a rail cutting jig...I haven't started yet but I already want a mini-mill  .

.

My question...what measuring devices did you use to build this 1911? I've seen builds where they used a 6" caliper, depth micrometer, outside micrometer, groove micrometer, etc. I came across a video of a guy that used a height gage to get the measurements to fit the sides of the barrel hood and it got me thinking. Couldn't a lot of the measurements to build a 1911/2011 be done with a height gage, test indicator and dial indicator? Would a depth micrometer even be needed with the above tools? Would a height gage really even be necessary?

I've so far picked up a .06-.250 gage pin set, I already have digital calipers (although I'm thinking about purchasing a better one) and I plan on buying a 0-1" outside micrometer. What else would you recommend?

My question...what measuring devices did you use to build this 1911? I've seen builds where they used a 6" caliper, depth micrometer, outside micrometer, groove micrometer, etc. I came across a video of a guy that used a height gage to get the measurements to fit the sides of the barrel hood and it got me thinking. Couldn't a lot of the measurements to build a 1911/2011 be done with a height gage, test indicator and dial indicator? Would a depth micrometer even be needed with the above tools? Would a height gage really even be necessary?

I've so far picked up a .06-.250 gage pin set, I already have digital calipers (although I'm thinking about purchasing a better one) and I plan on buying a 0-1" outside micrometer. What else would you recommend?

2011 frame rails do not lay flat like a 1911. Friend uses a Matrix Precision jig with very good results, he marries slide to frame. Cut may not be pretty but it doesn't matter and it will hold more oil than the finish from a keyway cutter. The more metrology tools you have, the better. When it comes to machinery purchases, buy bigger than you need (within reason). You will eventually have a project bigger than your machine's capacity. Creative work holding is the key. Machinery and tooling is a slippery slope, tooling can grow to 3X machinery cost. Make sure your friends bring the beer.

- Joined

- Mar 21, 2013

- Messages

- 4,063

@wrmiller I recently purchased two 80% 2011 frames and all the bits and pieces to build two 9mm's. I don't have a mill so I'm going to use a rail cutting jig...I haven't started yet but I already want a mini-mill.

My question...what measuring devices did you use to build this 1911? I've seen builds where they used a 6" caliper, depth micrometer, outside micrometer, groove micrometer, etc. I came across a video of a guy that used a height gage to get the measurements to fit the sides of the barrel hood and it got me thinking. Couldn't a lot of the measurements to build a 1911/2011 be done with a height gage, test indicator and dial indicator? Would a depth micrometer even be needed with the above tools? Would a height gage really even be necessary?

I've so far picked up a .06-.250 gage pin set, I already have digital calipers (although I'm thinking about purchasing a better one) and I plan on buying a 0-1" outside micrometer. What else would you recommend?

What you see in post #10 is pretty much it (the calipers are just barely in the pic on the right).

I mostly use my gauge blocks to measure the inside dimensions of the slide, and use the micrometer to verify the dimension of the gauge block (they're cheap). I like using the adjustable parallel to check for taper in the slide.

- Joined

- Nov 26, 2017

- Messages

- 1,516

That is a beautiful build. I love my 1911 but it is traditional 45ACP. It is my range gun and my daily carry. Love the fit in my hand.

You do amazing work. I was wondering what that slide would look like with a case hardening on it. I think the coloring would go very well with the frame. But that is just me.

You do amazing work. I was wondering what that slide would look like with a case hardening on it. I think the coloring would go very well with the frame. But that is just me.

- Joined

- Mar 21, 2013

- Messages

- 4,063

That is a beautiful build. I love my 1911 but it is traditional 45ACP. It is my range gun and my daily carry. Love the fit in my hand.

You do amazing work. I was wondering what that slide would look like with a case hardening on it. I think the coloring would go very well with the frame. But that is just me.

I think a darker case hardening/coloring pattern would look really cool. Probably not cheap, and not really in a position to do something like that at the moment. I will file the suggestion away just in case though.

- Joined

- Apr 27, 2020

- Messages

- 27

Got my 10mm finished up, maybe some fine tuning on the trigger left. I don't have quite the skill level as the OP, but working on it. Frame I used was out of spec from the get go, should have just tossed it but toughed it out, learned a lot about 1911's.

Two major "Out of spec" items on the Hellfire aluminum longslide frame was trigger bar ways overcut, and hammer slot not exactly centered.

Fusion barrel, although assured would work in a 6" Slide, was about .010 small at the 6" mark. Sent it back 3 months ago, countless emails, no barrel 7", 6", or otherwise yet, but that's a different story.

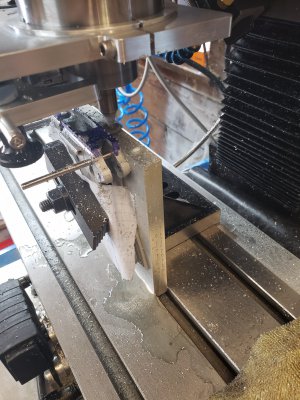

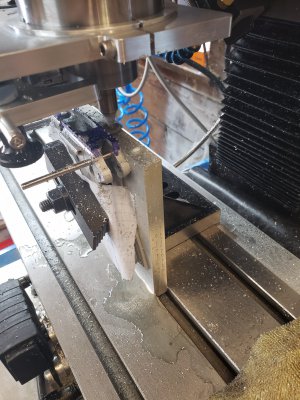

Trigger ways

original 7" barrel

Slide fitted, new 6" barrel fitted, now some fun stuff.

Two tries on the slide, blast, spray, bake, blast again and do over. still not super happy with the finish. The Stainless Steel Gray Alumahyde is exactly the same color as the sandblasted slide so hard to get an even coat. I may blast it off again and but a light coat of black before the gray.

Two major "Out of spec" items on the Hellfire aluminum longslide frame was trigger bar ways overcut, and hammer slot not exactly centered.

Fusion barrel, although assured would work in a 6" Slide, was about .010 small at the 6" mark. Sent it back 3 months ago, countless emails, no barrel 7", 6", or otherwise yet, but that's a different story.

Trigger ways

original 7" barrel

Slide fitted, new 6" barrel fitted, now some fun stuff.

Two tries on the slide, blast, spray, bake, blast again and do over. still not super happy with the finish. The Stainless Steel Gray Alumahyde is exactly the same color as the sandblasted slide so hard to get an even coat. I may blast it off again and but a light coat of black before the gray.