-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building a Pulse EDM machine

- Thread starter Mark_f

- Start date

Thank you, Nelson. This build kind of took a life of its own. I was inspired to make a simple tap burner by Savarin, when he explain his simple spark eroder. Having run an EDM in the past, I started researching EDM machines and found how to build one. As I learned more, I wanted to build a bigger, better, more useful machine. Well, as it kind of got out of hand,and my simple $50 spark eroder turned into a $1000 full blown EDM machine. I have no regrets building this machine as it will do machining that can't be done conventionally. I still have a way to go, but it is getting closer.This is a very educational build and will be a valuable addition to my shop. My progress is slowing due to financial constraints, but hopefully I can finish in the next 4 or 5 months and make some video tests upon completion.Mark

I sure you are as anxious as what we are watching. Thank for all the small lessons on how to: you are such a gifted man and sharing just help us all out.

Be well my friend

Nelson

Everyone keep watching and things will progress as swiftly as possible.

I made the hold down for the filter bag.

I cut a 6 inch ring from 1/2" thick PVC and put a 4" hole in it with a hole saw. I cut a recess to fit a 4" S&D PVC cap. The cap has 7 slots cut around it with a 1" end mill. The cap is cemented into the recess in the ring.

The ring sits on top of the bag filter ring to hold the bag in place. The slots allow the fluid to flow into the filter. There will be a spring beteen the top of this assembly and the lid to keep everything tightly in place.

I cut a 6 inch ring from 1/2" thick PVC and put a 4" hole in it with a hole saw. I cut a recess to fit a 4" S&D PVC cap. The cap has 7 slots cut around it with a 1" end mill. The cap is cemented into the recess in the ring.

The ring sits on top of the bag filter ring to hold the bag in place. The slots allow the fluid to flow into the filter. There will be a spring beteen the top of this assembly and the lid to keep everything tightly in place.

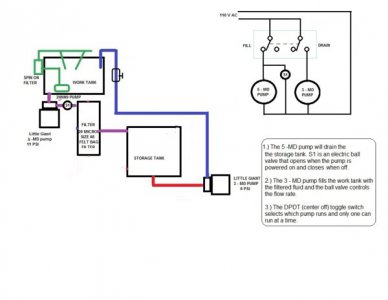

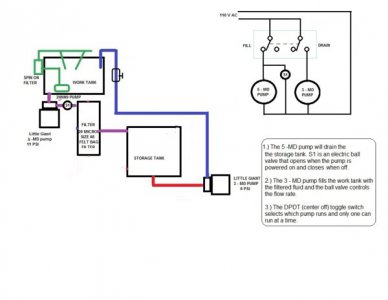

I have been working on several different designs for the fluid transfer system on this machine. The problems with the designs I have shown so far are they incorporate several ball valves to accomplish the needed tasks. While "I" can operate the system, it is not idiot proof. I'm trying to think of when I am gone and someone else acquires this machine, I want it to be like a commercial made machine and be more or less idiot proof. So I am still designing a system.

This is the latest thought.

This system would use two pumps. ( I have the pumps, so it is not a problem with the expense of them). I also have a high level sensor that will shut the fill pump off if the tank gets too full. It has the capabilities for a low level sensor also, which would prevent the drain pump from running once the tank was empty.

Any opinions are welcome. I want to have all the best features and the needed safety's for protection.

This is the latest thought.

This system would use two pumps. ( I have the pumps, so it is not a problem with the expense of them). I also have a high level sensor that will shut the fill pump off if the tank gets too full. It has the capabilities for a low level sensor also, which would prevent the drain pump from running once the tank was empty.

Any opinions are welcome. I want to have all the best features and the needed safety's for protection.

Mark

Was you able to come up with a spring? I was thinking the way the top cap holds the filter bag in place, do you think several smaller diameter springs mounted in a circle would work?

Nelson

I had thought of that. There is only a short distance between the lid and the piece that holds the filter in place. A short spring maybe 1 1/2" long will work. I can mount it to the centerpiece and the lid will compress it enough to hold it down. This way a spring about 1" diameter will work fine and I can get it at the hardware store.

I was going to use "eye" nuts ( like many of the commercial units use) to secure the lid until I saw the price of them

- Joined

- Mar 3, 2017

- Messages

- 744

I have been working on several different designs for the fluid transfer system on this machine.

This system would use two pumps. ( I have the pumps, so it is not a problem with the expense of them). I also have a high level sensor that will shut the fill pump off if the tank gets too full.

I had a fluid spill from an EDM (which, naturally, was working unattended)

once, and it was a mess. If possible, my preference would be for NO holes

in the bottom of tanks (suction from a dip tube instead, or submerge

the pump in the tank). Every valve and fitting that's above the tank

is under zero fluid pressure when the pumps are off. That's a happy thought.

Another thought, is that someday the fluid may be drained either for shipment

or for replacement; a way to redirect pump flow to a bucket could save some

messy bailing-with-tin-cans work. That seems to be present already (the

blue-handle valve in the loc-line assembly), if I'm interpreting the pix

correctly.