10 K is only internal grinding. External is about 4 kAt 10k rpm, you need a guard on the wheel too.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Building A Tool Post Grinder

- Thread starter Mark_f

- Start date

- Joined

- Apr 12, 2015

- Messages

- 1,463

Mark, meant to add in my comments that you have crafted an excellent grinder there! Thanks for posting it!

Never be afraid to post anything, even if it is something small.With all the fine projects posted by Mark (and others), I'd be embarrassed to post something from my garage

Nothing half done, very professional in every detail

I think for all the longer it runs at a time, cooling will not be a problem. I will be checking this and if needed I could add a small fan, but I don't think there will be a problem.Mark- looking very sharp. Question: Will the motor cover create a cooling problem? Do you need a fan or heat sink with that? Just something to consider.

Robert

T

TOOLMASTER

Forum Guest

Register Today

I may make one and use an air motorI have. it would make a nice compact unit.

- Joined

- Aug 22, 2012

- Messages

- 4,106

Logically the direction of the wheel against the work should be opposite to each other to get a higher differential between them but in reality isnt the speed of the grinding wheel so far above the speed of the workpiece that it wont make much difference?

I think you are basically correct, but I think there is a "friction" ( for lack of a better word) difference. Going the same direction, the higher speed (in my mind ) pulls the lower speed device. I assume this could affect the finish. I may all all wet here though. I figure that is why opposite directions would be better.Logically the direction of the wheel against the work should be opposite to each other to get a higher differential between them but in reality isnt the speed of the grinding wheel so far above the speed of the workpiece that it wont make much difference?

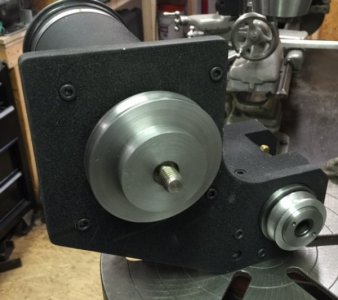

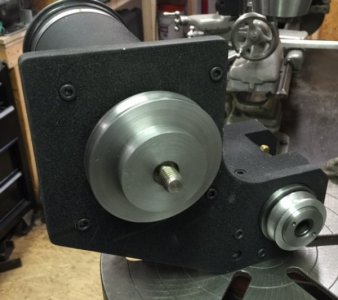

I got back on my tool post grinder today. I got the motor cover and motor pulley made.

The steel pulley is now mounted on the motor. tomorrow I will make the urethane round belt for the grinder. With this pulley, I calculate the top speed to be about 9,000 rpm. ( the wheels are good up to 30,000 rpm).

The steel pulley is now mounted on the motor. tomorrow I will make the urethane round belt for the grinder. With this pulley, I calculate the top speed to be about 9,000 rpm. ( the wheels are good up to 30,000 rpm).

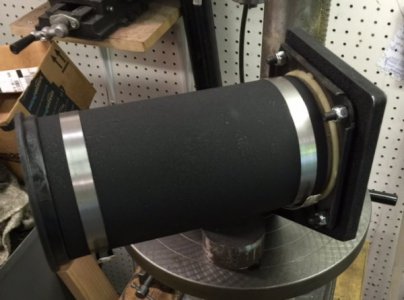

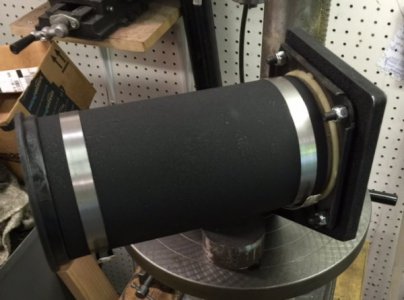

The motor cover is painted and held on with two band clamps. ( the ends will be trimmed off).

The motor cover is painted and held on with two band clamps. ( the ends will be trimmed off).

The end cover is installed and allows ventilation. You will never guess where this cover came from. It fit perfect with no alterations at all and looks great, even the right color. It is made of a tough ABS plastic material that is almost indestructible.

The end cover is installed and allows ventilation. You will never guess where this cover came from. It fit perfect with no alterations at all and looks great, even the right color. It is made of a tough ABS plastic material that is almost indestructible.

It is a 4 inch sewer grate cover for floor drains. The grinder has been painted with black wrinkle paint for durability and looks. The belt and belt cover are next and this project will be done and ready to use, so keep watching for the finish of this project. I built this project for some work on an upcoming project. My total investment in this project has been about $80. I raided scrap barrels for most of the material and scrounged up a very inexpensive ( as in free) tread mill motor.

I will post photos on the lathe for the test run.

The steel pulley is now mounted on the motor. tomorrow I will make the urethane round belt for the grinder. With this pulley, I calculate the top speed to be about 9,000 rpm. ( the wheels are good up to 30,000 rpm).

The steel pulley is now mounted on the motor. tomorrow I will make the urethane round belt for the grinder. With this pulley, I calculate the top speed to be about 9,000 rpm. ( the wheels are good up to 30,000 rpm). The motor cover is painted and held on with two band clamps. ( the ends will be trimmed off).

The motor cover is painted and held on with two band clamps. ( the ends will be trimmed off). The end cover is installed and allows ventilation. You will never guess where this cover came from. It fit perfect with no alterations at all and looks great, even the right color. It is made of a tough ABS plastic material that is almost indestructible.

The end cover is installed and allows ventilation. You will never guess where this cover came from. It fit perfect with no alterations at all and looks great, even the right color. It is made of a tough ABS plastic material that is almost indestructible.It is a 4 inch sewer grate cover for floor drains. The grinder has been painted with black wrinkle paint for durability and looks. The belt and belt cover are next and this project will be done and ready to use, so keep watching for the finish of this project. I built this project for some work on an upcoming project. My total investment in this project has been about $80. I raided scrap barrels for most of the material and scrounged up a very inexpensive ( as in free) tread mill motor.

I will post photos on the lathe for the test run.