- Joined

- Jul 26, 2020

- Messages

- 159

Recently, I've been getting back into photography. It's been a passion of mine since I was in high school, but I gave up on it because I had to figure out that whole "Adult" thing. I started shooting some photos this spring with an Olympus mirrorless camera and I got hooked all over again. A few months ago I picked up a Sony A7iii with some cheapish Sony lenses (50mm f2.8 macro, 50mm f1.8). Then I made the horrible mistake of renting a very nice (and very expensive) Sony 35mm f/1.4 GM lens. One thing lead to another and I now own a Sigma 35mm f/1.2 and a SIgma 85mm f/1.4. They are fantastic lenses, but they're also very expensive.

Then, I found out that I owed Uncle Sam a lot of cashola on the same day my two shiny new lenses came in. Oops. My fun budget is now gone for several months.

However, I still need a tripod with a good head. I've owned some junky Sunpaks and I'm sick of them. I want to make my own tripod, starting with the head. I know it won't be as light as some of the fancy composite stuff that's out today, but the point of having a machine shop is so that you can make massively overbuilt shiny things.

So, here's what I'm thinking:

Then, I found out that I owed Uncle Sam a lot of cashola on the same day my two shiny new lenses came in. Oops. My fun budget is now gone for several months.

However, I still need a tripod with a good head. I've owned some junky Sunpaks and I'm sick of them. I want to make my own tripod, starting with the head. I know it won't be as light as some of the fancy composite stuff that's out today, but the point of having a machine shop is so that you can make massively overbuilt shiny things.

So, here's what I'm thinking:

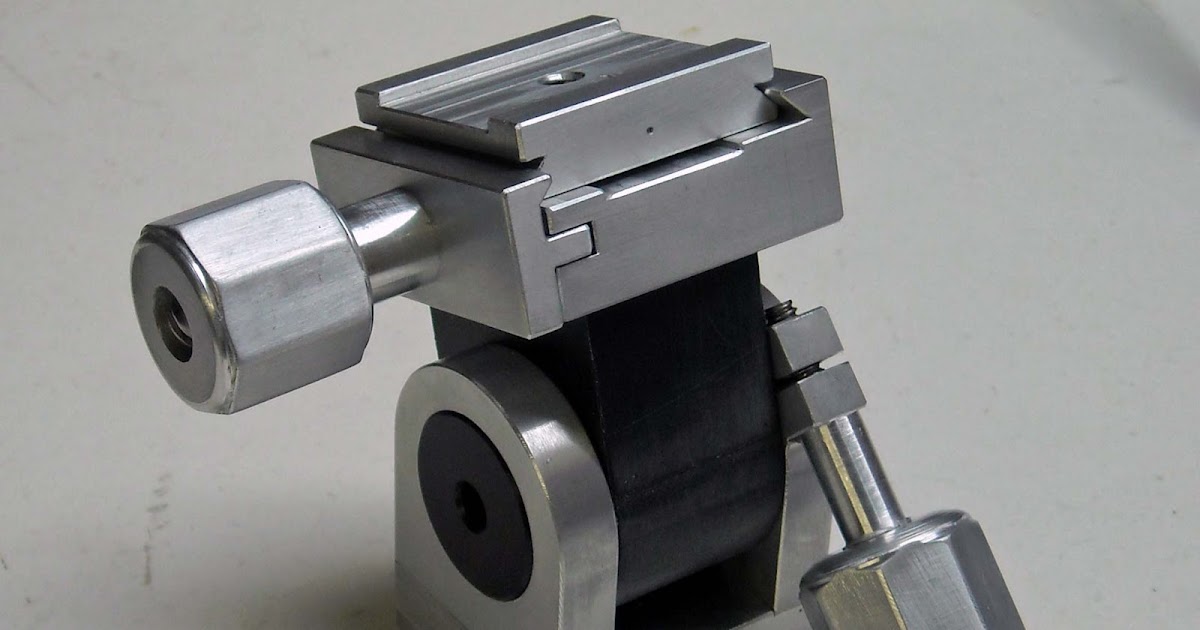

- The head will use an Arca-Swiss style mounting system

- This doesn't seem like the most convenient mounting system, but the plates are plentiful and it's compatible with a bunch of fun gadgets. Plus, it seems really secure!

- The head will be a pan head

- I won't be making a ball head. I don't have a ball turner, and I doubt I could hit the tolerances needed. Pan heads are slower, but I've used them and I think they're fine as long as they tighten quickly and firmly (I hate "squishy" pan heads)

- The head will prioritize stability and durability over weight

- I won't be hiking up a mountain with this tripod. Most parts will be steel. I have a lot of 4140PH on hand, but I may try to use stainless to avoid rust (I have 15-5, 17-4, Duplex 2205, Cronidur 30, and maaaybe some 303/304/316). Bearing surfaces will be bronze where needed (I don't have much bronze)

- Tolerances will need to be quite tight in some places if I want this head to lock up nicely, meaning there may need to be some form of dust exclusion (I live in a very dry and dusty place)

- Where possible, I'll prefer single parts over groups of parts. This will increase the machining time but should result in a maximally rigid head

- The head will be shiny and flashy

- I'm like a crow, I like shiny things. I have some nice brass offcuts that would make great knobs. I may use off-the-shelf screws for durability, but everything else will be bespoke to ensure maximum shininess