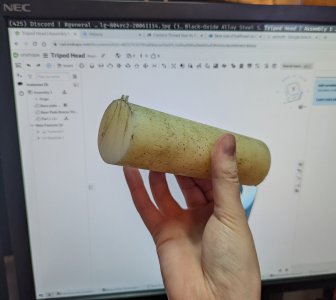

Here's the stock situation, by the way. I've attached some pictures with rough measurements and alloy types. I also have a 1.75" piece of what I believe to be PTFE, which should make an

awesome bearing material (although it'll be quite squishy).

View attachment 424173

There are no markings on it, but the color is right and it sinks quite quickly in water (the density of PTFE is 2.2 g/cm³, so it should drop pretty quickly).

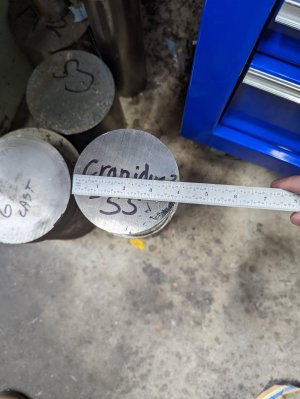

The big-ol block of 15-5 PH doesn't have any measurements, but it's quite large and it was too annoying to get my scale back there.