- Joined

- Nov 1, 2018

- Messages

- 98

Hello,

In this thread I'm going to show details of my new project - vertical CNC mill.

I've just started this project, so nothing is final. There might be some changes on a fly. However there are some practical limitations that put certain constraints on the built:

1. It's a small mill I can built in my garage, having access just to combo-lathe/mill;

2. There's old 12"x18" cast-iron surface plate, that can be used as a rigid base;

3. It's a single-column vertical mill, my surface plate isn't big enough to put the second column to make a router.

4. All the basic components are generally available in on-line stores and on eBay.

5. The mill has to be solid enough to machine aluminum.

6. There's no oiling system integrated - not using dovetails, only rails and slides.

7. Something I'll figure out later.

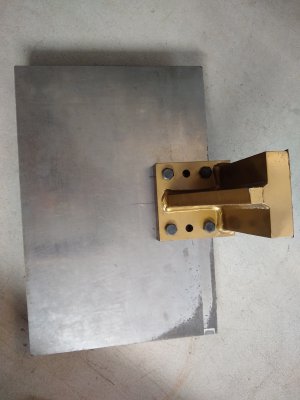

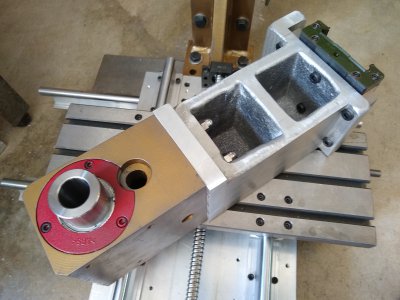

I started my built from the table. I bought the cast-iron one in LMS, that's the biggest table (400 mm x 145 mm) from the cheapest you can buy.

This one has dovetail that has to be removed to install the slides.

Here is Part 1 video on the table re-build

In this thread I'm going to show details of my new project - vertical CNC mill.

I've just started this project, so nothing is final. There might be some changes on a fly. However there are some practical limitations that put certain constraints on the built:

1. It's a small mill I can built in my garage, having access just to combo-lathe/mill;

2. There's old 12"x18" cast-iron surface plate, that can be used as a rigid base;

3. It's a single-column vertical mill, my surface plate isn't big enough to put the second column to make a router.

4. All the basic components are generally available in on-line stores and on eBay.

5. The mill has to be solid enough to machine aluminum.

6. There's no oiling system integrated - not using dovetails, only rails and slides.

7. Something I'll figure out later.

I started my built from the table. I bought the cast-iron one in LMS, that's the biggest table (400 mm x 145 mm) from the cheapest you can buy.

This one has dovetail that has to be removed to install the slides.

Here is Part 1 video on the table re-build