- Joined

- May 24, 2012

- Messages

- 395

After making a scissor knurling tool, I become intersted in making a straight knurling tool since it:

> is greath when you need transmit torque between a steel shaft and a plastic wheel.;

> it can bring me more choices when making stuff;

> I can "save" a interference mount part infortunatelly made too loose.

I took a 1/2" square and milled the wheel slot

Turned the 1/4" pin from a 1045 bar. Here you can see there a section slighty bigger for interference fit

Pin was heated red hot and quenched in water.

After welding the side tab and cross drilling the 1/4" hole, I pressed the pin

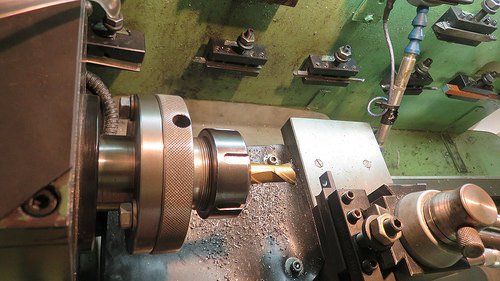

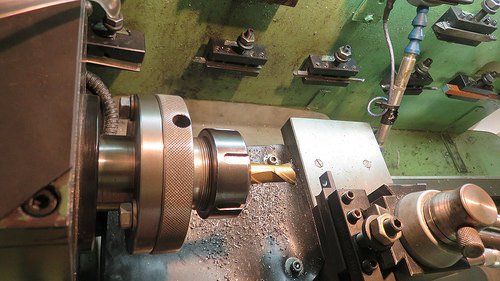

Test run. I've made a fine (0,8mm) and a coarse (1,25mm) wheel.

My knurl set

now waiting rain give a break for paint the tool

> is greath when you need transmit torque between a steel shaft and a plastic wheel.;

> it can bring me more choices when making stuff;

> I can "save" a interference mount part infortunatelly made too loose.

I took a 1/2" square and milled the wheel slot

Turned the 1/4" pin from a 1045 bar. Here you can see there a section slighty bigger for interference fit

Pin was heated red hot and quenched in water.

After welding the side tab and cross drilling the 1/4" hole, I pressed the pin

Test run. I've made a fine (0,8mm) and a coarse (1,25mm) wheel.

My knurl set

now waiting rain give a break for paint the tool

Last edited: