- Joined

- Mar 26, 2018

- Messages

- 8,407

Hey all,

I just finished a turkey sandwich

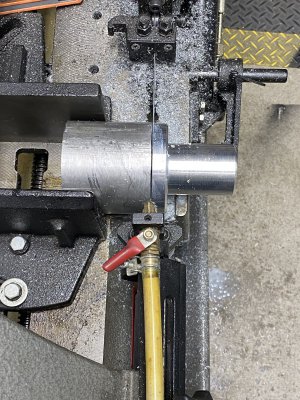

I have four of these to make. The first one took me way too long.

I don’t work aluminum very often. It took several attempts to figure out which insert, what speed and feed to produce chips rather than a long, sharp, hot curly snake that was coming at me.

At .012” feed per rev. running 625 rpm at .125” I found workable chips.

My insert is a WNMG332. The finish is good For what it is.

I ran a 3/8 pilot then went to my only MT4 taper drill, 1 5/64. Kept the bore to a minimum of time anyway.

I have three more to make, how would you do it.

Thanks for your ideas.

I just finished a turkey sandwich

I have four of these to make. The first one took me way too long.

I don’t work aluminum very often. It took several attempts to figure out which insert, what speed and feed to produce chips rather than a long, sharp, hot curly snake that was coming at me.

At .012” feed per rev. running 625 rpm at .125” I found workable chips.

My insert is a WNMG332. The finish is good For what it is.

I ran a 3/8 pilot then went to my only MT4 taper drill, 1 5/64. Kept the bore to a minimum of time anyway.

I have three more to make, how would you do it.

Thanks for your ideas.

Attachments

-

988A6C58-A837-4D0E-AE81-2CCD37FFF0C0.jpeg2.6 MB · Views: 44

988A6C58-A837-4D0E-AE81-2CCD37FFF0C0.jpeg2.6 MB · Views: 44 -

61A14240-5F6D-4F2D-B7B0-F3910F54BA46.jpeg2.3 MB · Views: 43

61A14240-5F6D-4F2D-B7B0-F3910F54BA46.jpeg2.3 MB · Views: 43 -

ABF8C73A-75FB-49DF-9D83-520F995D4C6C.jpeg1.8 MB · Views: 38

ABF8C73A-75FB-49DF-9D83-520F995D4C6C.jpeg1.8 MB · Views: 38 -

043B74E1-F717-4468-A5BA-5B7A45D8F20D.jpeg2.3 MB · Views: 41

043B74E1-F717-4468-A5BA-5B7A45D8F20D.jpeg2.3 MB · Views: 41 -

20F59CD9-A38F-4CC2-9BCA-98BED2ECDDE3.jpeg1.4 MB · Views: 47

20F59CD9-A38F-4CC2-9BCA-98BED2ECDDE3.jpeg1.4 MB · Views: 47