-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Buying A Torch For Silver Soldering - Advise Needed

- Thread starter Nogoingback

- Start date

- Joined

- Oct 18, 2016

- Messages

- 2,872

What size are you interested in? This will influence the choice of heat source.

I assume this question is for me. Like I said, my initial goal is to learn a new skill. Until I gain some knowlege

about what I can or cannot accomplish with that skill, it's hard to know what I'll be doing with it, even though I have some projects in mind initially. It's like when I got my first lathe: If you had asked what I planned on doing with it, I would have

had no answer for you. I just wanted to learn something new and it looked interesting. I've made lots of parts on my lathes since then, but I probably couldn't have anticipated any of them. So, we'll see.

Last edited:

- Joined

- Apr 23, 2018

- Messages

- 6,510

If you were putting a sight on a barrel, I would recommend oxy acetylene and a small 0 or 00 tip. If you mean that you will be laminating the sides of the skinny frame, that's a job for a furnace. The heat required for that solder will anneal your parts.

MAAP gas is hot enough for brazing most small items or thin cross-sections ( about 2900°C)

Air- Acetylene torches burn slightly cooler than the MAAP (about 2200°C)

I have been eyeing this Smith Acetylene-Air torch for similar applications - silver soldering & general heating to displace multiple MAAP bottles that are not exactly cheap either. The medium sized acetylene tank is a bit more convenient to my shop. When I called my local welding shop they rent/sell them quite a bit to HVAC & plumbers who need something a bit more portable.

Anyways my question. They quote 2632 degC so 400-ish higher than what you referenced. Is this one of those 'it depends' type specs?

The other system I hear a lot about in model engineering forums, maybe more Euro orientated, is Sievert propane systems. The BBQ cylinder & fillup is pretty convenient. The temps seem to range by burner type, I see reference between 400-720C

Sievert #3486 Pro 86 Single Valve Gas Torch Handle

Sievert #3486-47, Pro 86 Single Valve Gas Torch Handle. Provides flame adjustement with high quality construction. Inlet is LH 9/16 inch male thread. Price/Each.

www.bestmaterials.com

- Joined

- Feb 2, 2013

- Messages

- 3,622

the torches you have referenced may mix the air/acetylene better to achieve the higher temperature.Anyways my question. They quote 2632 degC so 400-ish higher than what you referenced. Is this one of those 'it depends' type specs?

the smaller nozzle tip may help in that regard as well

I just purchased a Smith Little Torch. I’m inclined to think it’s a Asian knock off because even though the box says Smith Little Torch, nowhere does it say made in USA. But it was only 30.00 on EBay . FWIW... USA sellers now have them for 20.00

That said... the tips were not precision drilled. So I cleaned up the tips using a tip cleaner,.... the ones with all the different gauge wire file/ reamers.

And then I went to hook it up to the tote tanks.. my old regulator leaked. So I purchased the SAU regulator set. I love this little torch. Awesome ! For Silver Brazing it’s the cats meow. I was having trouble brazing small items with my Miller 100 series rig. But this little torch is just fantastic for small items.

That said... the tips were not precision drilled. So I cleaned up the tips using a tip cleaner,.... the ones with all the different gauge wire file/ reamers.

And then I went to hook it up to the tote tanks.. my old regulator leaked. So I purchased the SAU regulator set. I love this little torch. Awesome ! For Silver Brazing it’s the cats meow. I was having trouble brazing small items with my Miller 100 series rig. But this little torch is just fantastic for small items.

Attachments

Last edited:

- Joined

- Oct 18, 2016

- Messages

- 2,872

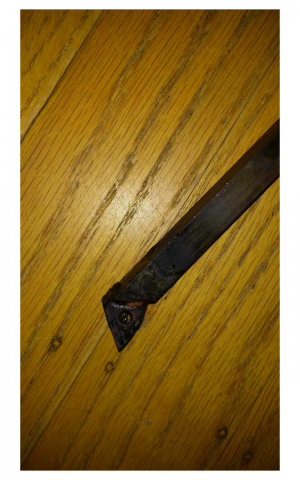

First Attempts:

I went ahead and bought some Muggyweld SSF-6 and gave it a try this evening. My first try was an utter failure, so I went

back and reviewed the videos from Muggyweld. This is my second attempt, which I think is satisfactory, even though a bit

untidy. I probably used more rod than needed, but it left a fillet that won't hurt anything. I did this with propane.

I bought the firebrick from High Temp, Inc. in Portland: they manufacture them and will sell small quantities to hobbyists. These are high

temp bricks (3000 deg.) and cost a bit more than 5 bucks a piece. Tractor supply charges more than $2.50 now.

I went ahead and bought some Muggyweld SSF-6 and gave it a try this evening. My first try was an utter failure, so I went

back and reviewed the videos from Muggyweld. This is my second attempt, which I think is satisfactory, even though a bit

untidy. I probably used more rod than needed, but it left a fillet that won't hurt anything. I did this with propane.

I bought the firebrick from High Temp, Inc. in Portland: they manufacture them and will sell small quantities to hobbyists. These are high

temp bricks (3000 deg.) and cost a bit more than 5 bucks a piece. Tractor supply charges more than $2.50 now.

Last edited:

- Joined

- Oct 18, 2016

- Messages

- 2,872

Thanks!