- Joined

- Feb 2, 2013

- Messages

- 3,625

My brother has a 1894 F250 4x4 diesel pickup, that he got from our dad who bought it new.

my brother is rebuilding the front end from the bearings, to tie rod ends to universal joints in the independent front end.

he needed a tool to install the front drive hub needle bearing.

the needle bearing is inside the front axle hub.

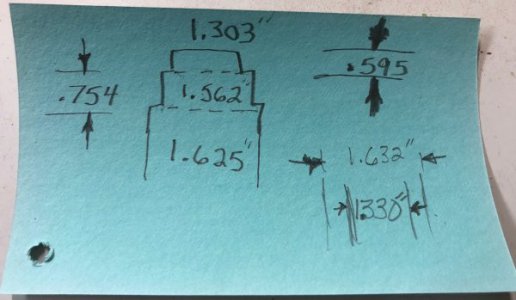

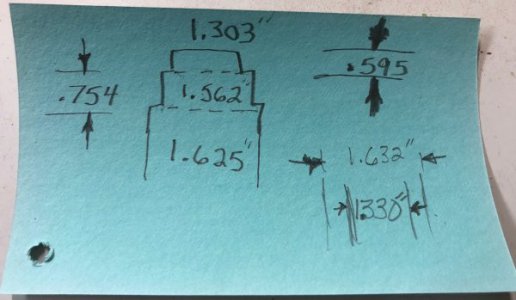

after removal of the old needle bearing, i was able to make a installation tool from 1-5/8", 7075 aluminum.

here are the pictures...

the tool woorked great and he was able to put the axle through the hub!

thanks for looking!

my brother is rebuilding the front end from the bearings, to tie rod ends to universal joints in the independent front end.

he needed a tool to install the front drive hub needle bearing.

the needle bearing is inside the front axle hub.

after removal of the old needle bearing, i was able to make a installation tool from 1-5/8", 7075 aluminum.

here are the pictures...

the tool woorked great and he was able to put the axle through the hub!

thanks for looking!

. Many of those bearings were BUSHINGS, back in the 70's. If you are in THAT deep, pull the axle shaft and check the axle U-joint and the surface this bearing rides on. I will bet it is tired too. Might as well change the axle shaft seal at the diff housing too. Since you are THAT deep, might as well pull the diff down to check differential and pinion bearings. The pinion seal will start leaking soon, just cuz it feels left out.

. Many of those bearings were BUSHINGS, back in the 70's. If you are in THAT deep, pull the axle shaft and check the axle U-joint and the surface this bearing rides on. I will bet it is tired too. Might as well change the axle shaft seal at the diff housing too. Since you are THAT deep, might as well pull the diff down to check differential and pinion bearings. The pinion seal will start leaking soon, just cuz it feels left out.