- Joined

- Dec 7, 2015

- Messages

- 519

It took me a couple days to get this done, and rather uncharacteristically I took almost no photos of the guts of the project. I picked up a 4" digital caliper from Harbor Freight and converted it to use as a DRO on the Z axis on my Millrite. The project really turned out well and I think this will be a much needed addition.

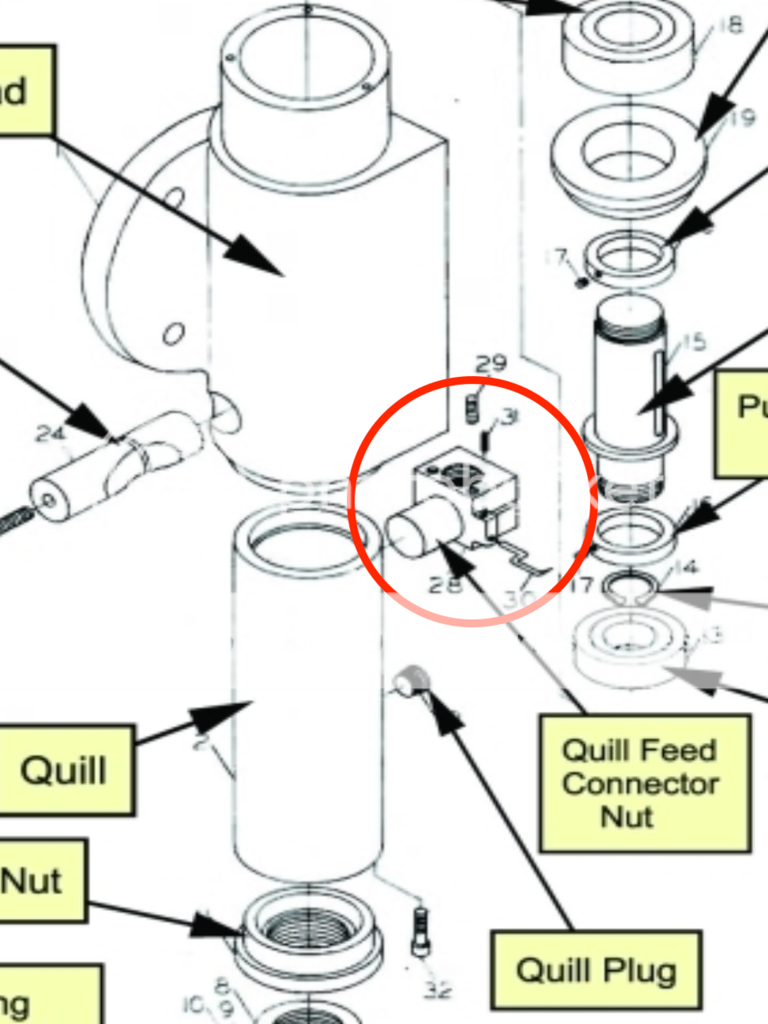

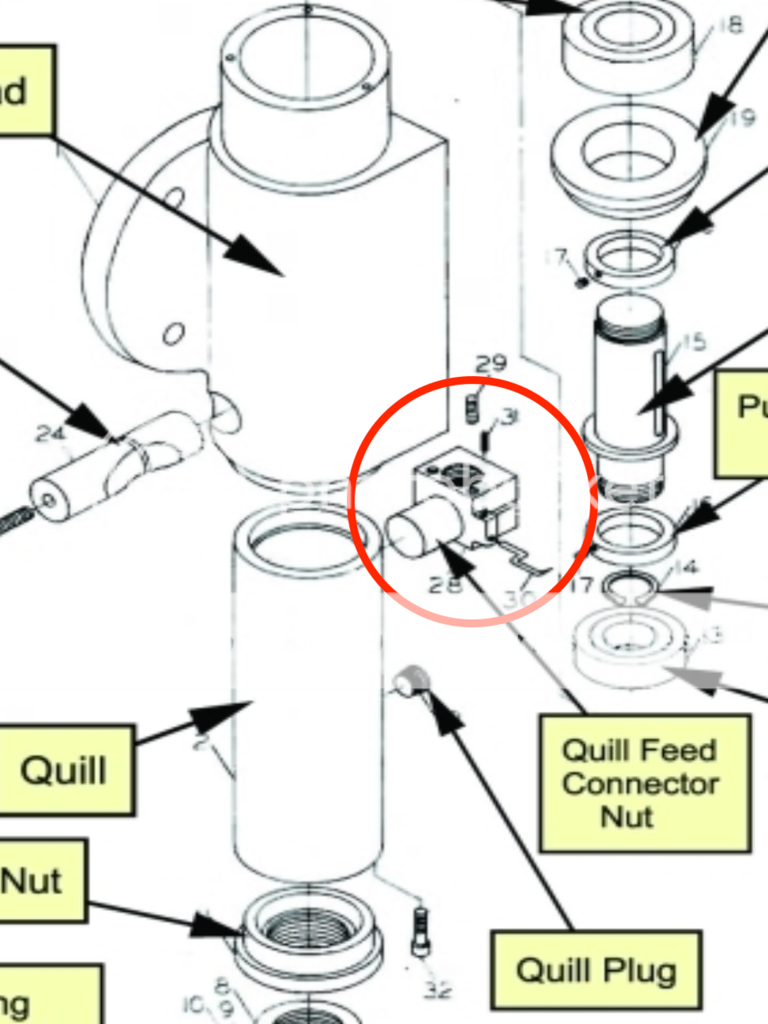

To borrow a photo from Mike Amick's webpage, I modified the quill feed connector nut by removing the needle and grinding down that nub that the needle fits into. There was a grub screw that held the needle in place. All of this was ground away.

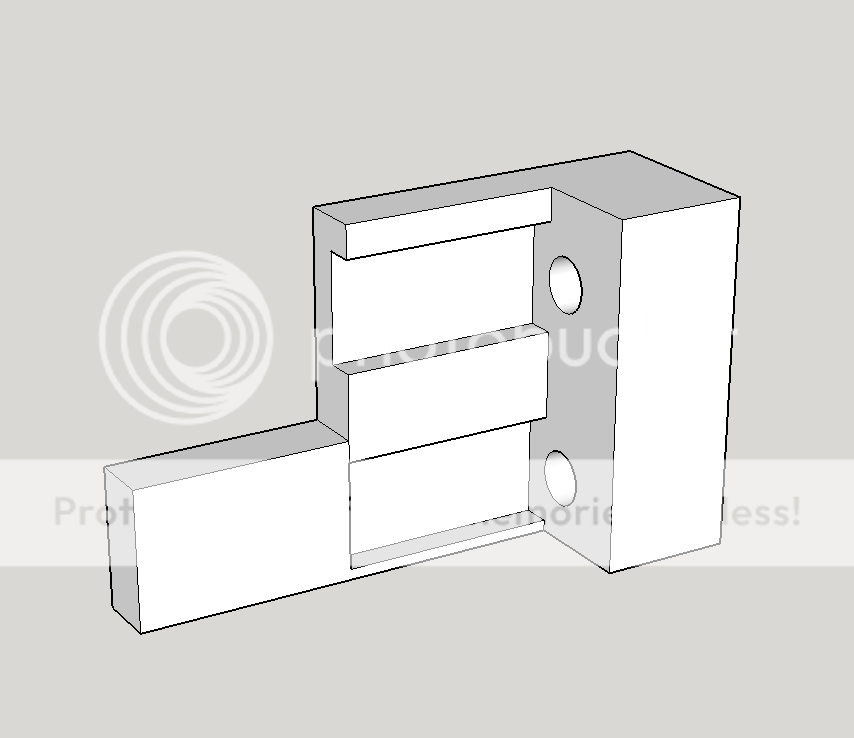

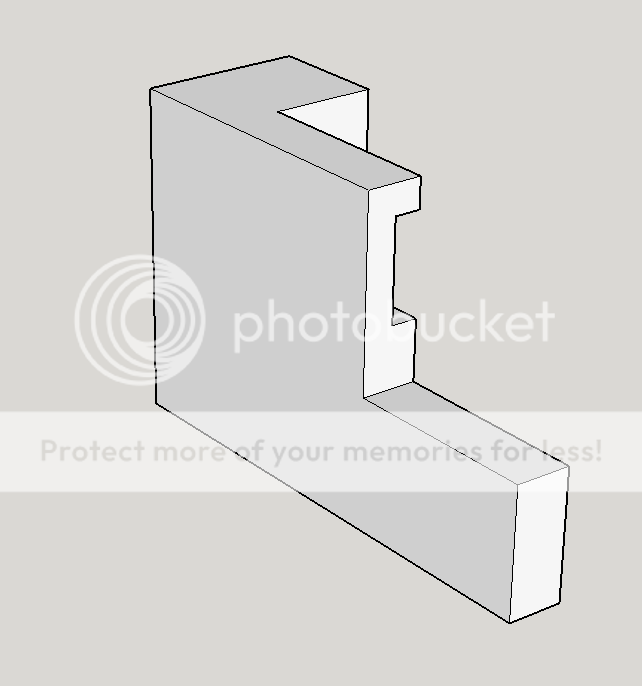

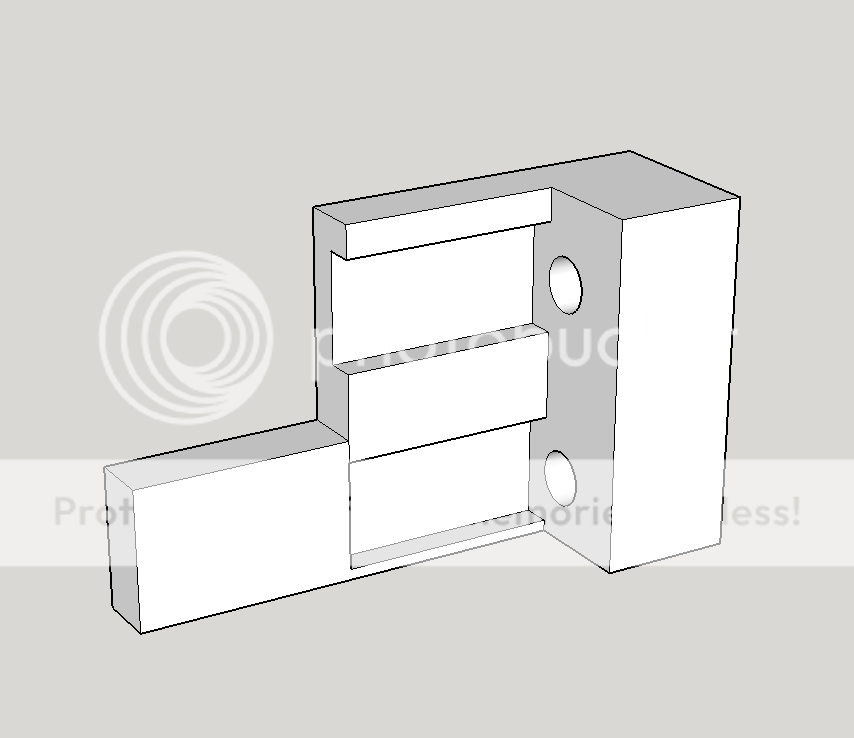

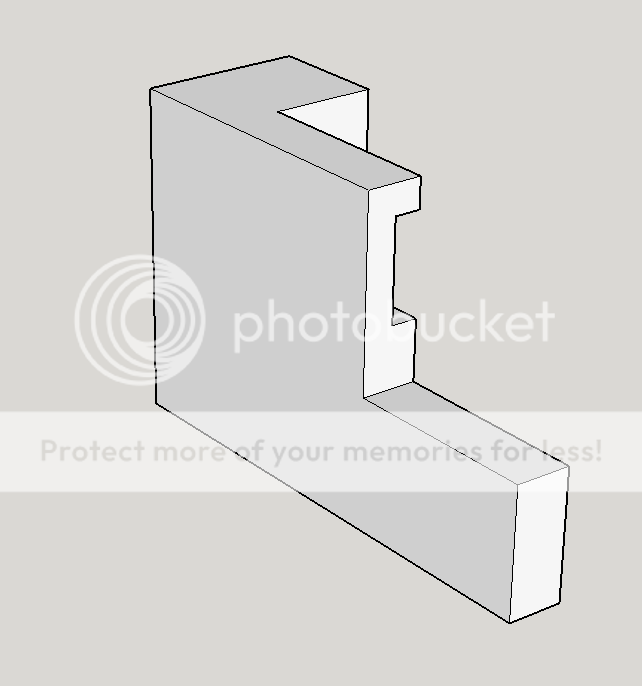

The resulting flat area was drilled and threaded 6-32 and I machined a piece of aluminum roughly this shape to bolt onto the connector nut.

The machine was reassembled (actually- I had to take it apart multiple times to adjust and tweak the fit) and the caliper was screwed to the newly machined piece. I did modify the caliper by grinding off the unneeded jaws. I drilled the two screw holes using a carbide end mill which made quick work of it.

I'm very pleased with how it turned out, and especially with how well it works. Here is a video I shot for some friends on Facebook, but I'll share here too. Check it out here:

To borrow a photo from Mike Amick's webpage, I modified the quill feed connector nut by removing the needle and grinding down that nub that the needle fits into. There was a grub screw that held the needle in place. All of this was ground away.

The resulting flat area was drilled and threaded 6-32 and I machined a piece of aluminum roughly this shape to bolt onto the connector nut.

The machine was reassembled (actually- I had to take it apart multiple times to adjust and tweak the fit) and the caliper was screwed to the newly machined piece. I did modify the caliper by grinding off the unneeded jaws. I drilled the two screw holes using a carbide end mill which made quick work of it.

I'm very pleased with how it turned out, and especially with how well it works. Here is a video I shot for some friends on Facebook, but I'll share here too. Check it out here: