- Joined

- Jan 3, 2015

- Messages

- 400

I've only threaded a couple of pieces on my LMS3540, and never experienced the problem I've run into this weekend. A few months ago, while making a steam engine kit, it needed a 1/4-28 thread cut on a quarter inch shaft. I did a couple of practice pieces, and a 1/4-20, which is pretty similar.

This weekend I had a small stud on a part I was machining that needed to be threaded 6-32. The only die I have wouldn't get close enough to the part body to thread it (too much taper), so it seems like a natural to do on the lathe. When I put the proper gears on, there's mechanical interference and the driven gear won't engage with the change gears.

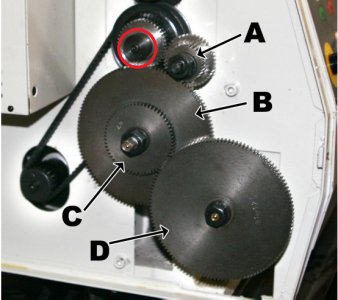

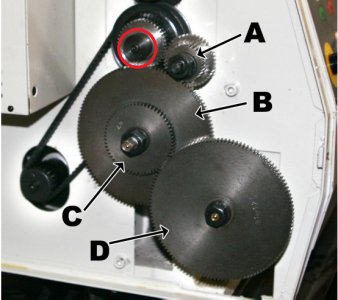

These lathes, like other Sieg lathes, use a set of four gears, A-D, as pictured here:

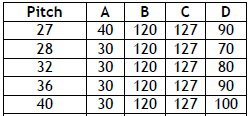

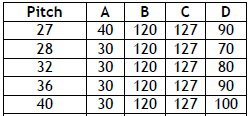

To thread something, you change the gears over to the required set:

I post this to point out that there is one minor difference between the gears I used successful, the 28 pitch and the 32 pitch: on the 32 pitch the last gear is 80 tooth vs 70 on the 28 pitch.

When I put the 80 tooth gear on, I have to move the B/C gears farther out an arm (left in the picture) they're mounted on, and then it interferes with a bushing on the driving gear (circled in red). The B gear (inner one) never meshes with the driving A gear. The 70 tooth gear works fine, and I also changed over to the smaller gear used for the 20TPI screw (50 tooth) and it works. It seems as the D gear gets bigger, it mechanically doesn't fit.

I put on the 100 tooth gear required for a 40TPI screw and the interference moves from that bushing over to the enclosure you can see on the left. The B/C gears hit that enclosure and never get within a few inches of the gear on A they're supposed to mesh with.

That makes it seem like it's impossible for the SC4 to cut these pitches.

Web searches turn up nothing about this, but this is probably the place to ask. Does anybody know about this? Been able to thread 32 TPI? Can you see anything stupid I'm doing?

This weekend I had a small stud on a part I was machining that needed to be threaded 6-32. The only die I have wouldn't get close enough to the part body to thread it (too much taper), so it seems like a natural to do on the lathe. When I put the proper gears on, there's mechanical interference and the driven gear won't engage with the change gears.

These lathes, like other Sieg lathes, use a set of four gears, A-D, as pictured here:

To thread something, you change the gears over to the required set:

I post this to point out that there is one minor difference between the gears I used successful, the 28 pitch and the 32 pitch: on the 32 pitch the last gear is 80 tooth vs 70 on the 28 pitch.

When I put the 80 tooth gear on, I have to move the B/C gears farther out an arm (left in the picture) they're mounted on, and then it interferes with a bushing on the driving gear (circled in red). The B gear (inner one) never meshes with the driving A gear. The 70 tooth gear works fine, and I also changed over to the smaller gear used for the 20TPI screw (50 tooth) and it works. It seems as the D gear gets bigger, it mechanically doesn't fit.

I put on the 100 tooth gear required for a 40TPI screw and the interference moves from that bushing over to the enclosure you can see on the left. The B/C gears hit that enclosure and never get within a few inches of the gear on A they're supposed to mesh with.

That makes it seem like it's impossible for the SC4 to cut these pitches.

Web searches turn up nothing about this, but this is probably the place to ask. Does anybody know about this? Been able to thread 32 TPI? Can you see anything stupid I'm doing?