- Joined

- Jan 3, 2015

- Messages

- 400

Hi Guys,

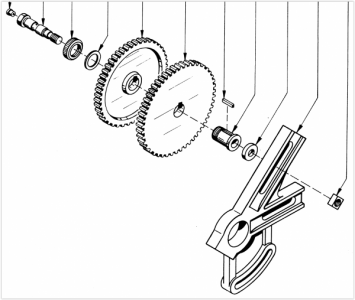

I'm sure that I've seen somewhere that someone had made a new banjo/banjo's for his lathe. I know that there is at least one design for a replacement banjo for my lathe. The slot is about 12 mm (1/2") too short to fit certain gears. To be honest, I don't remember what the gear size was, other than it was one in the chain. I do remember that in order to use the 127 tooth gear, you can't close the cover, but it doesn't protrude like the one in your picture.

I don't see how that could be my problem. It's not that the gear wasn't far enough out on the banjo, it's that there is mechanical interference out there. If the gear couldn't reach where it's going, that's one thing, but on the SC4 the problem was the gear was hitting something else, the drive gear (for the 32 pitch) or that enclosure (for the 40 pitch).

Last edited: