- Joined

- Dec 13, 2016

- Messages

- 164

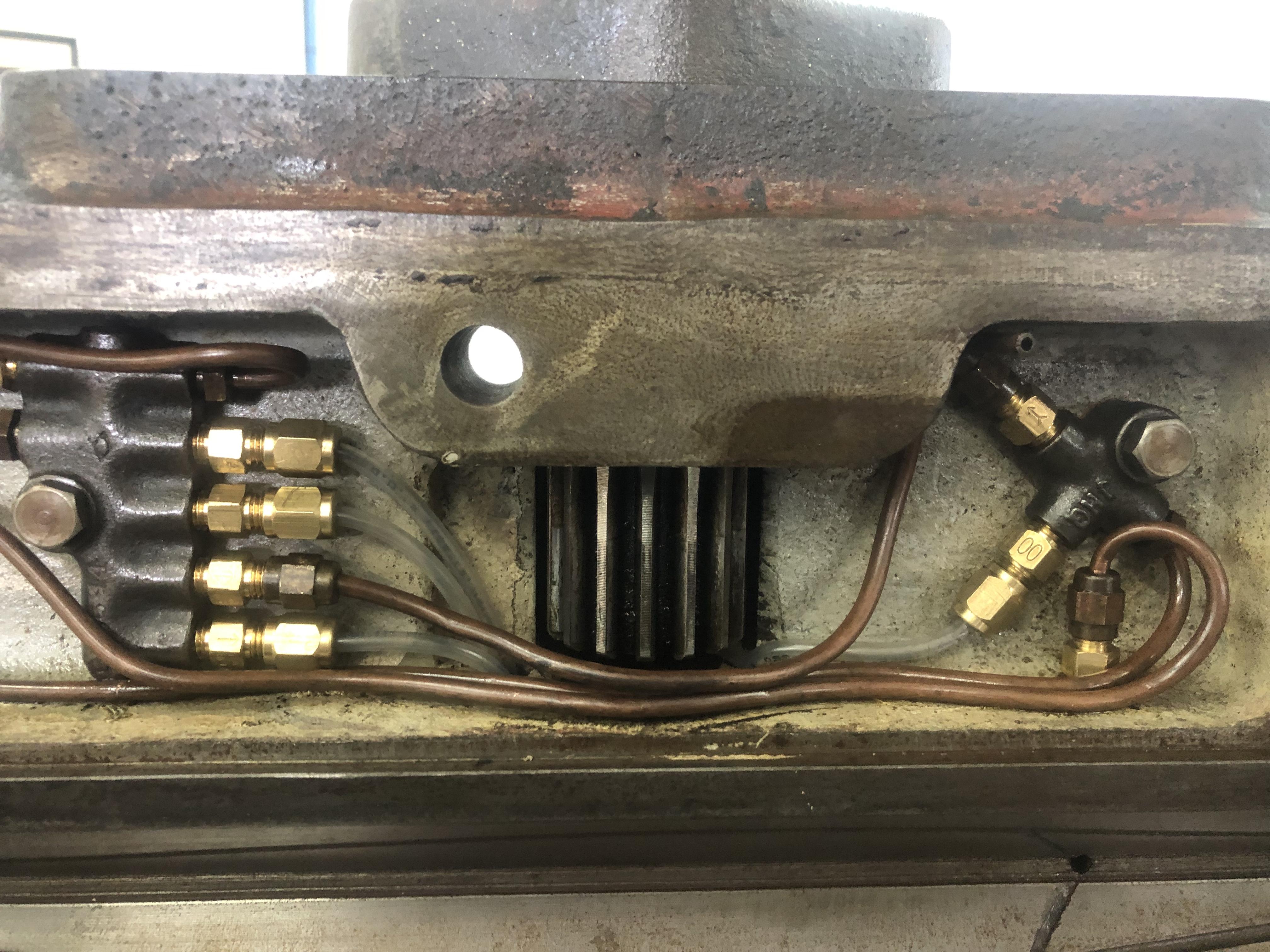

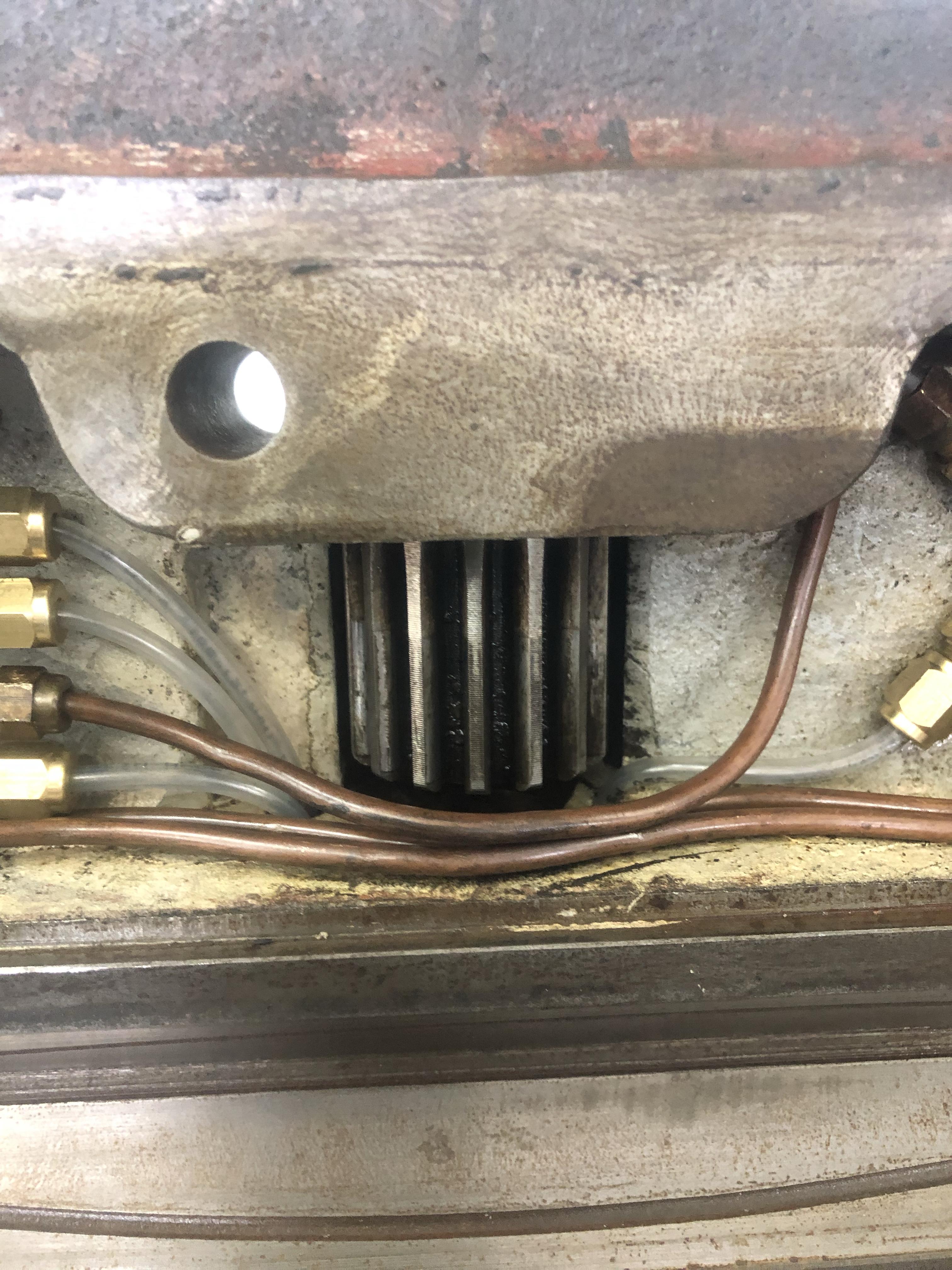

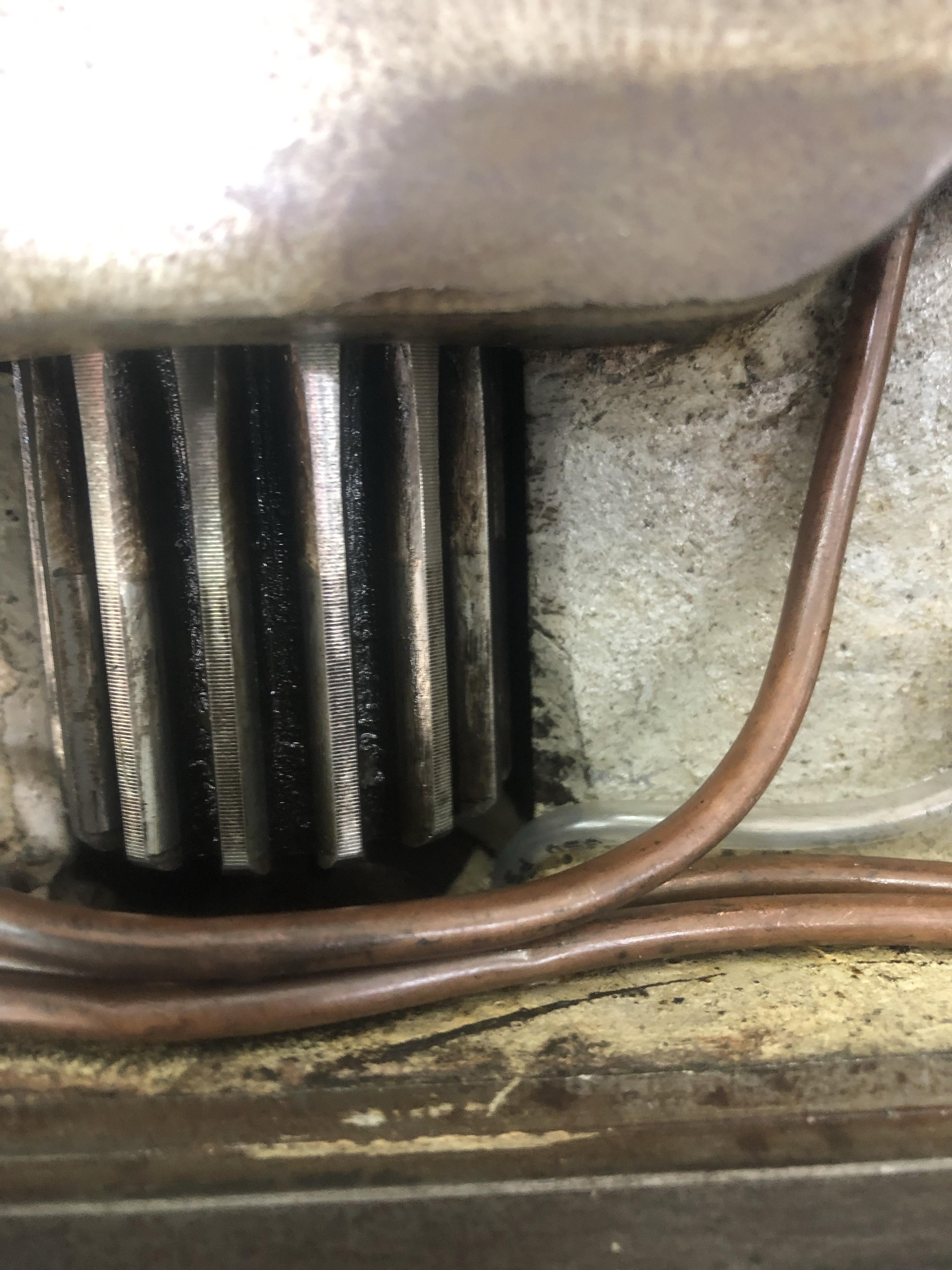

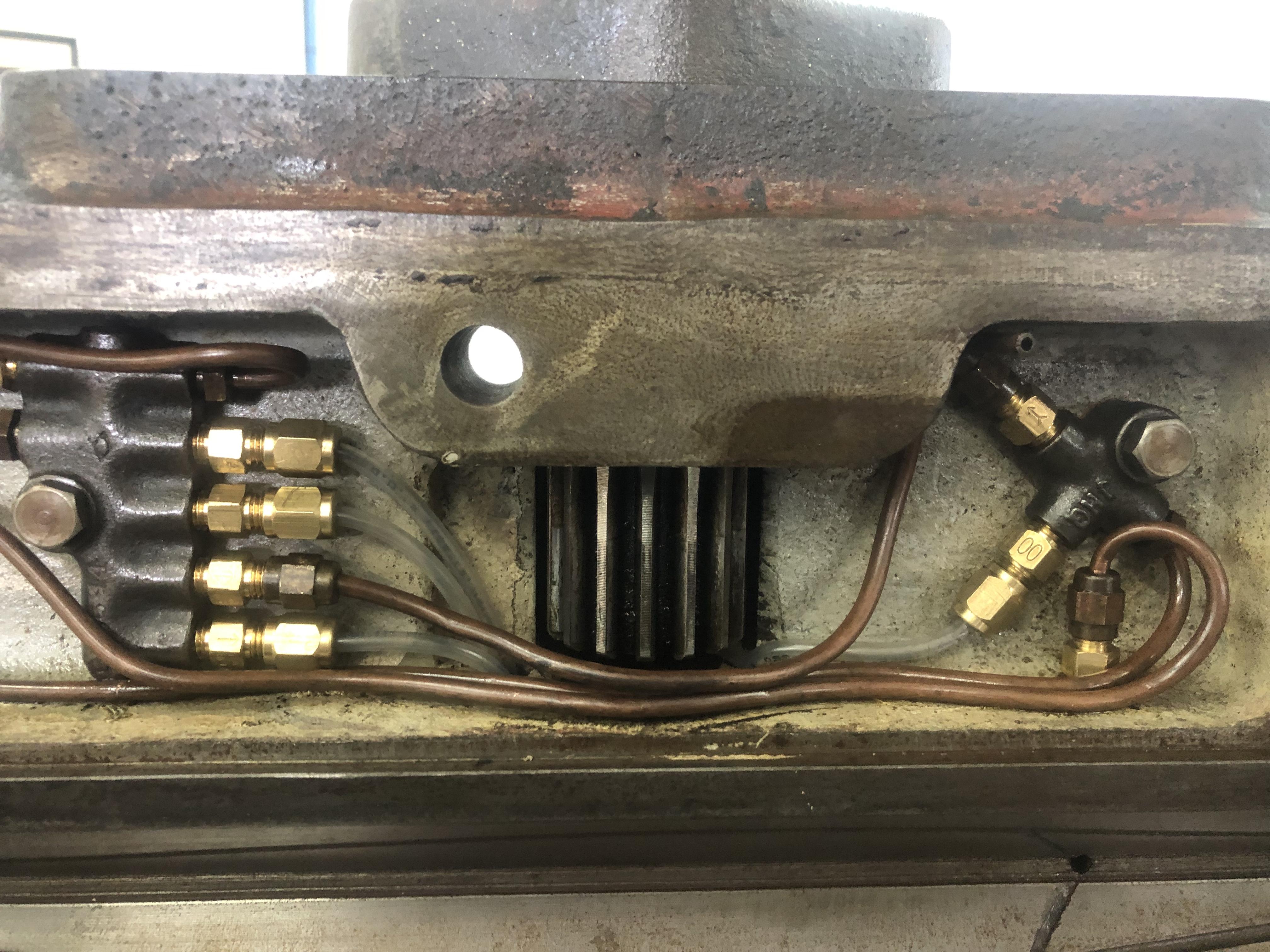

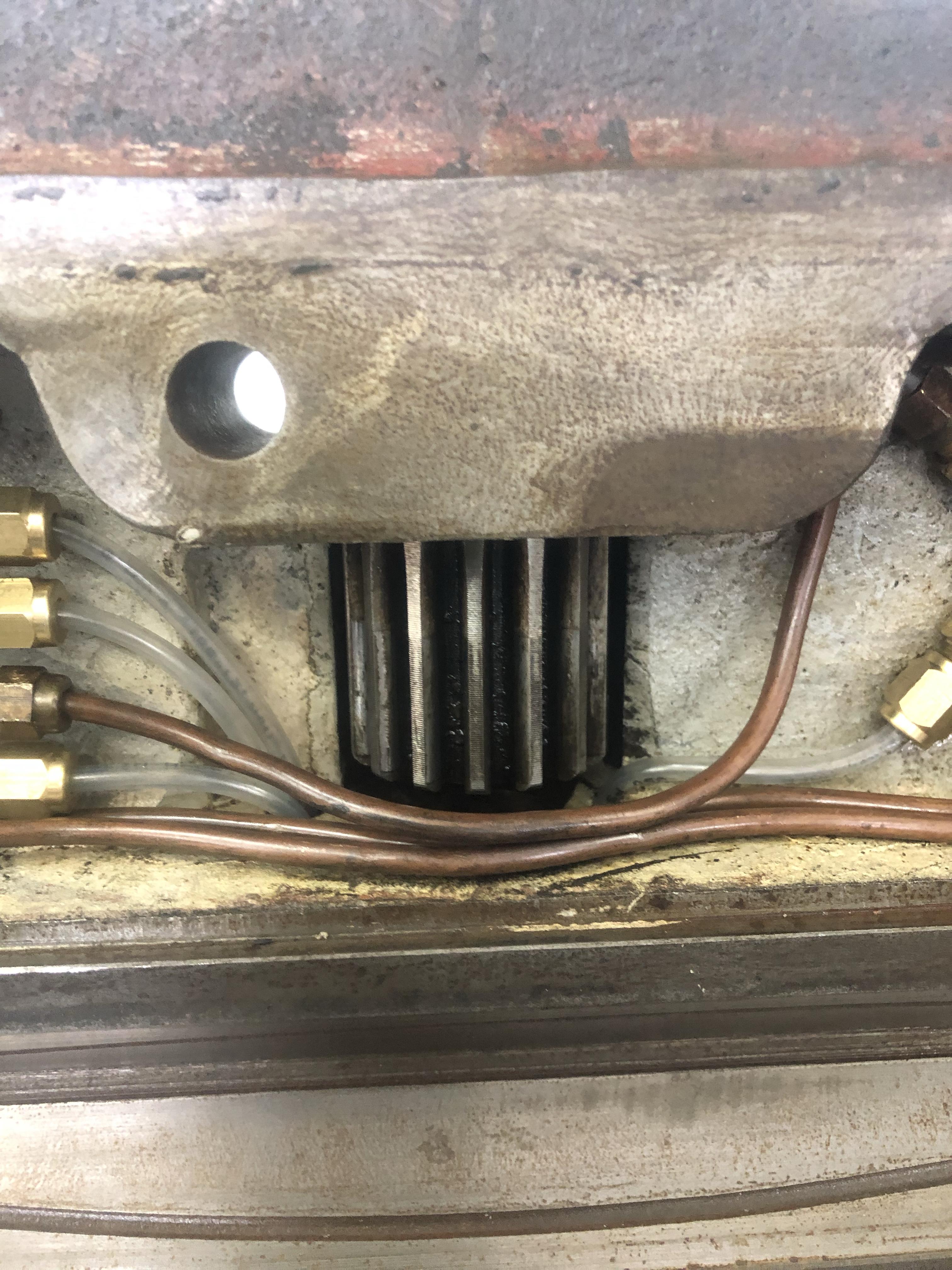

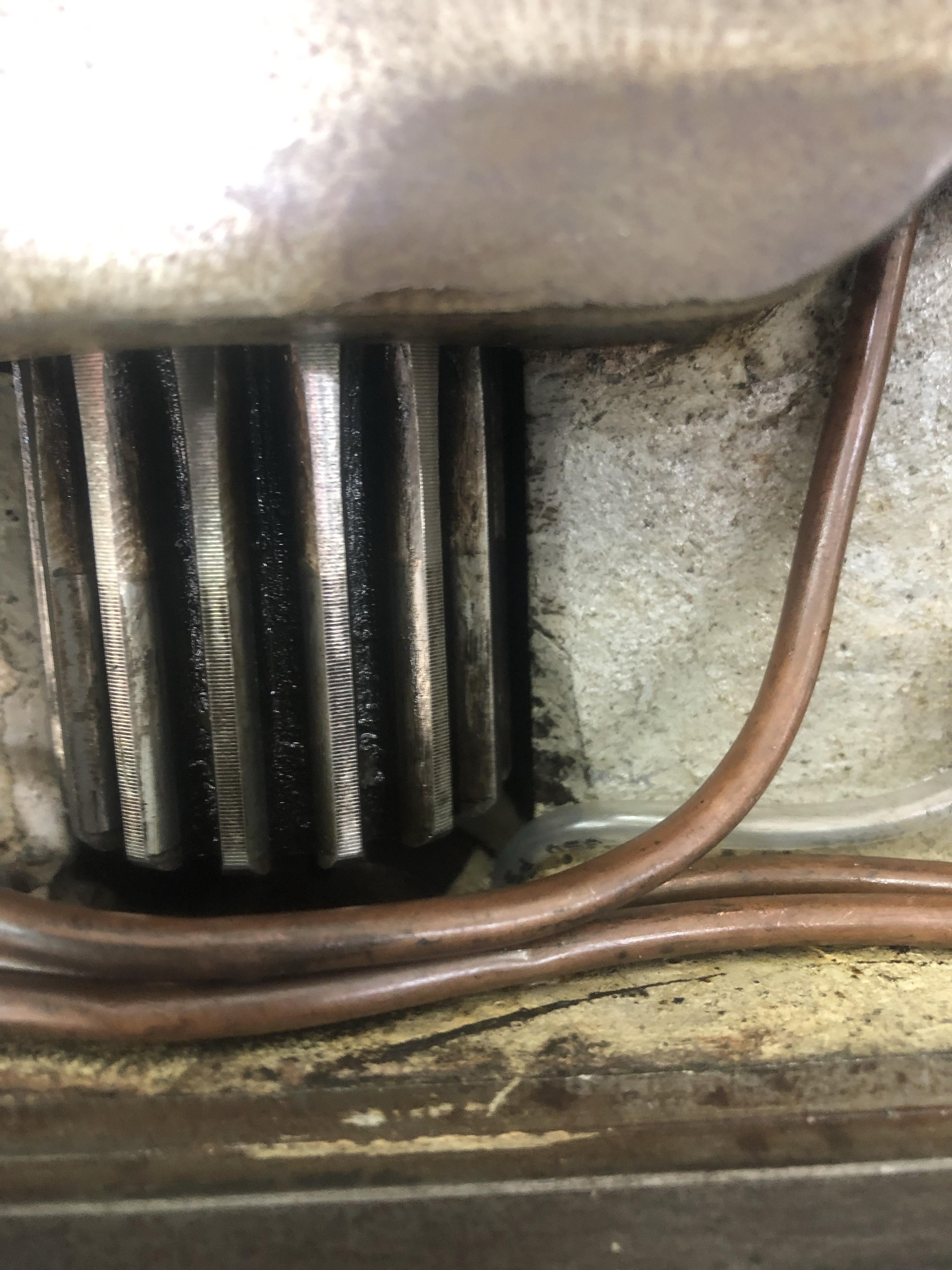

This has been discussed but never saw anyone actually do it. I got frustrated with replacing the oil lines in the carriage on my 18CBB with the copper lines. So I yanked them out and ordered some 5/32 clear nylon tubing. Used the compression fittings as well. This stuff worked great! Easy to handle and manage. I did not have to do any heavy bends so that was a plus. Here are some pics. I only need to replace the lines that went to bed ways and the cross slide. I got all the lines pulled taunt with no kinks. Used a heat gun and applied a little heat to the lines and held them in place close to the casting and let cool. This prevented any bulging that you will see in the pics below.

I then used Bondo All-Purpose Putty to seal and protect the lines. It’s a sandable and fast drying putty and can chip out if needed.

I did pressure checked everything and lube hits all points. The screw and compound gear clears all the lines.

So tomorrow I will get this back on the lathe and continue to march.

Sent from my iPhone using Tapatalk

I then used Bondo All-Purpose Putty to seal and protect the lines. It’s a sandable and fast drying putty and can chip out if needed.

I did pressure checked everything and lube hits all points. The screw and compound gear clears all the lines.

So tomorrow I will get this back on the lathe and continue to march.

Sent from my iPhone using Tapatalk